Guideline for Pharmaceutical and Medical Device Batch Record Review

- Published on: Oct 27, 2017

Standard Operating Procedures (SOP) shall be established at each site to describe the batch record or Device History Record (DHR) for products manufactured, packaged, or tested at the Site.

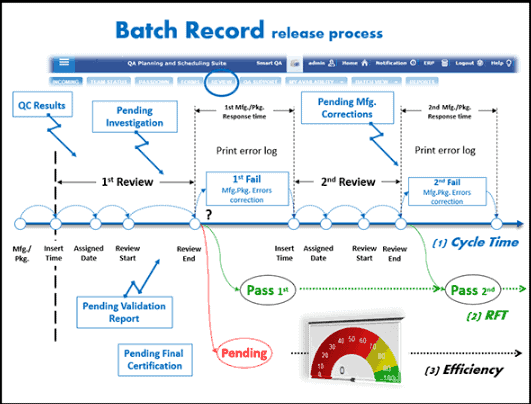

The Site Quality Team shall be responsible for the final review and Approval of completed batch records or DHR, and associated Control Records.

- For Drug Products, all steps are subject to Site Quality Team review.

- For APIs, the Site Quality Team shall determine the processing steps where the batch record is subject to a Quality Team review.

- For Medical Devices, all steps are subject to Site Quality Team review.

For batch records requiring Site Quality Team review, the Site Production Team shall be responsible for reviewing production batch records, assuring those records are complete and accurate, and signing the batch record, signifying the review was performed and the production records are accurate and complete, prior to forwarding to the Site Quality Team for final review.

For DHR requiring Site Quality Team review, the Site Production Team shall be responsible for reviewing production records, assuring those records are complete and accurate, and signing and dating the DHR, signifying the review was performed and the production records are accurate and complete, prior to forwarding to the Site Quality Team for final review.

For API Steps or Intermediates Where no Site Quality Team Review is Required, the Production Team shall be responsible for the review and approval of the batch records to assure the records are complete prior to a Disposition being assigned to the batch.

The Production Team shall inform the Quality Team of any Deviations discovered during the Production Team batch record review. Any deviations shall be Investigated and documented as described in the internal deviation procedure.

Disposition of Batches and Lots shall be performed in accordance with the requirements with internal release procedure

A Document (e.g., SOP, Batch Record, or DHR Review Checklist) shall be established at each Site that outlines the specific information and/or specific documents that must be reviewed and included in the batch record or DHR.

Batch Records or DHR Review by the Production Team shall include review of the following:

- Results of any in-process tests or inspections;

- Documentation of applicable environmental conditions (Air Classifications, temperature, relative humidity);

- Documentation of Raw Materials, Starting Materials, Packaging Materials, Component used, including specific identification & quantity

- Documentation of equipment preparation (e.g. cleaning records, Sterilization records, filter

Integrity Test records);

- Calculations are correct (significant figures);

- Sample of Labeling used; and

- Documentation of samples collected.

In addition:

For Drug Product:

- An accurate reproduction of the Master Manufacturing Instruction with documentation that each step was executed and documented;

- Yield calculation and Accountability;

- Documentation of manufacturing line cleaning and clearance;

- Documentation of packaging line cleaning and clearance; and

- Documentation of final quantity manufactured and packaged.

Batch Records or DHR Review by the Production Team

For API:

- An accurate reproduction of the Master Manufacturing Instruction with documentation that each step was executed and documented; and

- Documentation of bulk product filled and packaged, including lot identification and quantity.

For APIs, batch records review by the Production Team may also include, based upon local regulatory requirements and steps defined by the Site Quality Team, accountability and yield calculations.

For Medical Devices:

- Batch has been produced following approved and current Device Master Record (DMR);

- Documentation of manufacturing line cleaning and clearance;

- Documentation of packaging line cleaning and clearance; and

- Documentation of final quantity manufactured and packaged.

For Drug Product or Intermediates shipped to non affiliate sites, and APIs Requiring Review by the Site Quality Team, the batch record review shall include Verification of the following items:

- Required documentation is included in the records;

- Required data entries have been made;

- Batch has been produced following approved and current Master Batch Record;

- Production Team has signed the record to signify that the production records have been reviewed and are complete and accurate;

- Production Materials were approved prior to use in production and were still within the Expiration Date or Re-evaluation Date when used;

- Calculations shall be verified as complete and accurate, however, when a Validated Computerized System is used for calculations, no verification is necessary; and

- Applicable environmental monitoring data are within specified limits.

In addition:

For Drug Product:

- Batch was produced within Process Parameter ranges;

- Results from In-Process Controls (IPC) and finished product testing for compliance with Regulatory Specifications (RS);and

- Accountability and Yield calculations.

For APIs:

- Results from Critical In-Process Controls (IPC) and finished product testing for compliance with RS; and

- Batch was produced within Critical Process Parameter Ranges.

For API, Site Quality Team Review of a batch record may also include, based upon local regulatory requirements and steps defined by the Site Quality Team, verification of accountability and yield calculations.

For Intermediates for further processing on site or by other sites requiring review by the Site Quality Team. The Site Quality Team batch record review shall include verification of the following items:

- Results from Critical In-Process Controls (IPC); and

- Batch was produced within critical process parameter ranges.

Site Quality Team Review of a DHR for Medical Devices shall include verification of, but not be limited to, the following items:

- Required documentation is included in the records;

- Required data entries have been made;

- Batch has been produced following approved and current DMR;

- Production Team has signed the record to signify that the production records have been reviewed and are complete and accurate;

- Production materials and/or components were approved prior to use in production and were still within the expiration date or re-evaluation date when used;

- Calculations shall be verified as complete and accurate, however, when a validated computerized system is used for calculations, no verification is necessary;

- Applicable environmental monitoring data are within specified limits.

- Documentation of manufacturing line cleaning and clearance;

- Documentation of packaging line cleaning and clearance; and

- Documentation of final quantity manufactured and packaged.

If a data entry field on quality control record or a batch record or DHR is not filled or is missing data, an explanation must be documented in the batch record or DHR. If no explanation is provided, a deviation investigation must be initiated.

Missing Data for Critical Process Parameters shall only be allowed to be added to the batch record or DHR after a deviation has been initiated, the reason for the batch record or DHR missing the data is investigated and there is independent documented evidence to support the information. If the data are added, the person adding the data shall sign and date the addition and reference the supporting documented evidence. The step shall also be reviewed, signed and dated by the Quality Team.