How to perform metal detection in pharmaceuticals processes

- Published on: Feb 03, 2022

Why use of metal detection is important in pharmaceuticals processing?

Sophisticated metal detection can save your business from loss of revenue and reputational damage. Metal detection ensure your products are safe to consume at the same time comply with regulatory requirements.

Imagine a tablet filling line where the core tablets are fed from an intermediate bulk container into a hopper & vibrator tray. The try is vibrating gently to help the vacuum dust collector to suck the loose particles away.

This plastic hose is collecting and transferring the tablets from the vibrator tray to a tablet feeder. The feeder tubes are helping the individual tablets to sit on the recently formed blister pockets.

Sensors are detecting any hole on the blister web. The vision camera system is taking pictures from the top of the blisters before being sealed with a foil and displays on a screen if there is any rouge tablet.

Sealing station is sealing the blister foil and printed lid foil with correct alignment.

Suddenly an alarm went off at the metal detector which is installed in-line. The operator shuts down the filling process, report the incident to Supervisor and investigation begins.

Any presence of metal into packed tablet will be seen as extremely harmful contamination to patients and the batch can possibly be quarantined and destroyed. The company will be forced to count heavy loss from the metal contamination of the product.

Your company could have avoided such a loss by introducing metal detectors at the earlier stages of processing lines. Possibly during the processing of raw materials and environmental monitoring of the site.

Where and when to use metal detection in pharmaceutical process?

Your decision on whether to use routine metal detection for your products should be based on the following factors:

– Product history of metal contamination incidents (e.g., equipment failures, equipment metal-to-metal contact causing contamination, raw materials with metal contaminants etc.)

– Assessment of manufacturing and/or packaging processes involved in terms of possible metal contamination

– Effectiveness of the metal prevention systems and processes used at the site, and

– Commitments to regulatory authorities.

If you have high level of historical incidents of metal contamination you should install and train metal detectors in those critical processing steps. Typically, metal detectors are used at following locations routinely:

– In the manufacturing process, install metal detector immediately after the tablet press or encapsulation machine

– If a de-duster is used in the tabletting or encapsulation process, install a metal detector immediately after the de-duster, and

– install a metal detector in the packaging line, immediately after the bottle filling process.

You should document the rationale for placement of the metal detectors as a preventive measure where the risk of contamination is high.

240 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

What to consider in operation of metal detection equipment?

While purchasing a new metal detector you should consider the following:

– Must have robust detection sensitivity

– Have noise filters and seals

– Have reject gate rotonoids. (Rotonoid is the double acting electrical solenoid valve that is electrically controlled in two directions (e.g., open and closed) with no spring return.

– Detectors are cleanable

– Have internal seals to reduce radio frequency interference

– Have static grounding measures

– Have necessary alarms, either audible or light post or both, and

– Means to verify and acknowledge the fact that rejects went into reject bin.

During the installation you should position the metal detector such that the detector does not interfere with the process and the detector is not in contact with adjacent manufacturing or packaging equipment.

Any chutes or conveyors passing through detectors should be aligned to not interfere with reject gate operation.

Metal detection equipment set-up and operating parameters for each product or process combination should include and are not limited to:

– Clean and dust-free environment during set-up

– Correct sensitivity settings for each product or product group

– The reject gate reaction and delay time, when a reject gate is used

– Length of time reject gate stays open

– Throughput speed; and

– Correct chute and chute alignment for aperture size.

How to qualify and setup metal detector sensitivity?

Metal detectors sensitivity settings should be assessed during equipment installation such that:

– Good product (i.e., product that may contain metal but less than the detection level) is not rejected; and

– The cylinder carriers that are used to challenge the metal detector are detected and rejected.

If either of these tests fails, the metal detector should be re-adjusted.

1. Manufacturing processes

You should qualify metal detectors used in manufacturing operations (e.g. encapsulation and tabletting process) with 100 percent certainty that it can detect and isolate spherical 0.5mm ferrous, spherical 0.5mm non-ferrous and spherical 0.8mm stainless steel metal embedded in discs or cylinder carriers that are used to challenge the system.

2. Packaging operations

You should qualify metal detectors used in packaging operations, for instance bulk tablet filling in such sensitivity that it can detect and isolate spherical 1.0mm ferrous, spherical 1.0mm non-ferrous and spherical 1.5mm stainless steel metal embedded in discs or cylinder carriers that are used to challenge the system.

3. Critical process parameters

You should identify and document critical process parameters and ranges as part of the metal detector qualification. This should include and are not limited to:

– Reject gate reaction time, if reject gates are present

– Length of time reject gate stays open

– Throughput process speed, and

– Sensitivity settings

4. Installation qualification

Metal detector installation qualification (IQ) should include verification that:

– Metal detector is installed according to specifications

– Utilities (e.g., electrical, air supply) are identified and the direction of flow indicated when necessary; and

– Routine preventive maintenance measures are established.

5. Operational qualification

Metal Detector Operational Qualification (OQ) should include the following:

– Alarm tests

– Test for radio frequency interference

– Challenge metal detectors used in manufacturing and packaging operations with respective specifications while the processes are performing at their maximum validated throughput rate

– Sensitivity settings for each product or group of products with the same product signal noise are established

– Reject gate reaction and delay time for each product or group of products with the same product signal noise is established; and

– Length of time that reject gate stays open is established.

The metal detector sensitivity settings should be verified and documented by a qualified operator during the set-up operation.

Try our FREE online GMP Skill Booster tests. It’s challanging, it’s refreshing and it’s FREE. Try now!

How to conduct challenge testing of metal detector sensitivity?

You should conduct in-line metal detector challenges at the beginning of the process equipment running.

Each challenge should consist of three passes of the challenge disc/cylinder through the aperture. Such in-process challenge tests should be performed and documented at a minimum information of:

– Lot/batch number to start-up

– After re-starting equipment (e.g., after breaks, shift changes, or downtime exceeding two hours); and

– At the end of a batch/lot.

– Challenge metal detectors used in manufacturing operations with discs/cylinders containing spherical 0.5mm ferrous, 0.5mm non-ferrous, and 0.8mm stainless steel metal

– Challenge metal detectors used in packaging operations with discs/cylinders containing spherical 1.0mm ferrous, 1.0mm non-ferrous, and 1.5mm stainless steel metal

How is the metal detected and what to do next?

Metal detectors have built in sensors that can detect metallic particles such as fine particles, corrosions, pins, buds, flakes etc. through electromagnetic induction mechanism, radio signals transmission etc.

Your products and raw materials can be contaminated by unwanted equipment failures, metal-to-metal contact or metal introduced by rusty and dusty environments.

Metal detectors are equipped with audible and/or visual alarms. Production Operators in the vicinity of the equipment should be signalled when metal is detected, and the in-process goods are diverted or isolated.

1. In-process control

You should establish in-process control (IPC) limit for the number of units isolated for each process or product. Any excursions from the in-process control limit should be evaluated during processing.

Note: This in-process control limit during processing is separate and distinct from the end of processing action limit.

2. Action limit determination

Action Levels for the total number of units (e.g., tablets, capsules, bottles) isolated by the metal detector should be developed by the quality team based on but not limited to:

i. Historical data on the number of units contaminated with metal according to product and/or manufacturing or packaging process step

ii. Investigation reports [e.g., deviation reports including any documented product recovery from contaminated units, and

iii. Applicable quantitative results indicating that preventive measures have reduced metal contamination in manufacturing and/or packaging process steps. Such preventive measures include and are not limited to:

– Installation of rare earth magnets at raw material charging stations;

– Raw material process improvements by the vendor that reduced contamination; and

– Manufacturing or packaging equipment set-up improvements that reduced contamination resulting from equipment wear.

3. Investigation

You should investigate and document if the quantity of units isolated by the metal detector exceeds the action limits. The lot should not proceed to another processing step until the quality team reviews the investigation report and determines the status of the lot.

Product units (e.g., tablets, capsules, packaged units) that are isolated by the metal detector should not be returned to the acceptable units unless an investigation reveals an assignable cause.

Such product units should be placed in quarantine-Hold status pending the completion of the investigation.

Product units that are found acceptable on re-inspection may be returned to the acceptable units of the lot being processed, with the approval of the quality team.

Re-inspection should be performed following a written and approved protocol or site standard operating procedure (SOP). Product units that are isolated by the metal detector during re-inspection should be rejected and not returned to the acceptable units.

Such rejected product units should be collected in a dedicated container that is properly labelled as to its contents (e.g., “Metal Detector-Rejects”).

Accountability of units with metal contaminants should be summarized in the investigation report when a process deviation causes metal contamination.

Rejected units may be dissolved in a solvent and evaluated to determine metal type and source, if feasible, as part of the investigation.

Accidental introduction of metal during a process step should result in the process immediately being stopped and an investigation conducted. The operation should not continue until the quality team has reviewed the investigation and approves continuing the process.

Summary

There are many types of metal detections used in pharmaceutical processes during raw material mixing, bulk preparation such as tableting, encapsulation, liquid formulation etc. Metal detectors also employed during packaging operations.

The location of metal detectors in your process will depend on critical processing steps and historical contamination data. As a prevention from metal contamination iIt is important keep your environment free from rust and dust.

Metal detectors need to be trained and challenged before employed in your process to avoid false alarms.

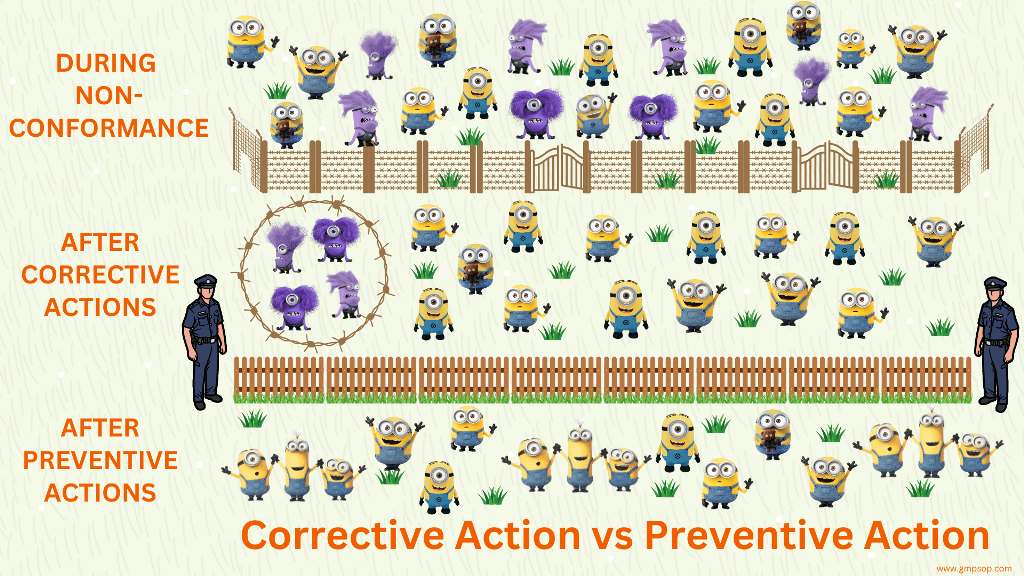

You should investigate all metal contamination incidents properly, determine the roost cause and implement preventive actions to stop recurring incidents in future.

240 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

Line clearance procedure and reconciliation in GMP

Corrective and Preventive Action (CAPA) Procedure for GMP

Equipment cleaning procedure in pharmaceutical, Do’s and Don’ts

Very interesting