Good Practice for Container Closure Integrity for Sterile Drug Products

- Published on: Oct 27, 2017

The Suitability of All Container Closure Systems for Sterile Drug Products manufactured and/or packaged by the GMP site shall be determined. The Effects of Environmental Stresses, Handling, and Simulated Use on Container Closure suitability shall be determined for new or changed container closure systems.

The Container Closure Sealing Process for sterile drug products shall be Validated to ensure that the integrity of the container closure system will protect the product over its shelf life. Written and Approved Standard Operating Procedures (SOP) shall describe packaging/sealing equipment set-up, operation, and maintenance. Equipment and systems used in the sealing processes for packaging sterile drug products shall be qualified or validated. Validation Studies shall be conducted by Qualified personnel and shall be documented.

Critical Process Parameters and Critical Process Parameter Ranges that affect container closure integrity shall be identified during the validation process for each container closure configuration.

The Microbial Ingress Test shall be used to validate the integrity of the container closure system. The immersion method shall be used unless another method is justified (e.g., aerosol method).

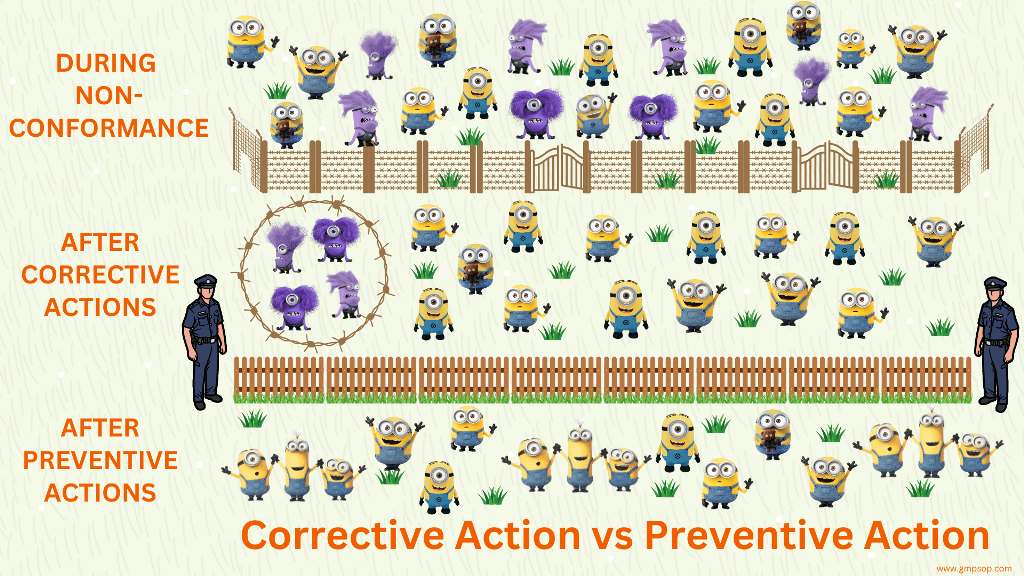

Non-Microbial Methods for Container Closure Integrity Testing [e.g., Residual Seal Force (RSF)] shall be used during routine production and shall be correlated to the microbial ingress test. In-Process Control (IPC) sampling for container closure integrity testing shall be representative of the packaged lot. Sampling and test procedures shall be written and approved.

Action Levels and Specifications for Non-Microbial Methods for Container Closure Integrity Testing shall be established and validated for drug products sealed in glass vials having elastomeric closures.

Product Containers Sealed by Fusion (e.g., Glass and Plastic Ampoules) and Form-Fill-Seal (FFS) shall be one hundred (100) percent integrity tested.

Product Packaged to Maintain Vacuum or Gas Headspace shall be tested for maintenance of the vacuum or gas headspace at specified intervals over the product shelf life.

Stability Samples shall be tested for container closure integrity over the shelf life of the product and at Batch/Lot Expiration Date.

Instruments and Elements used to monitor, control or test container closure integrity shall be Calibrated according to an approved schedule.

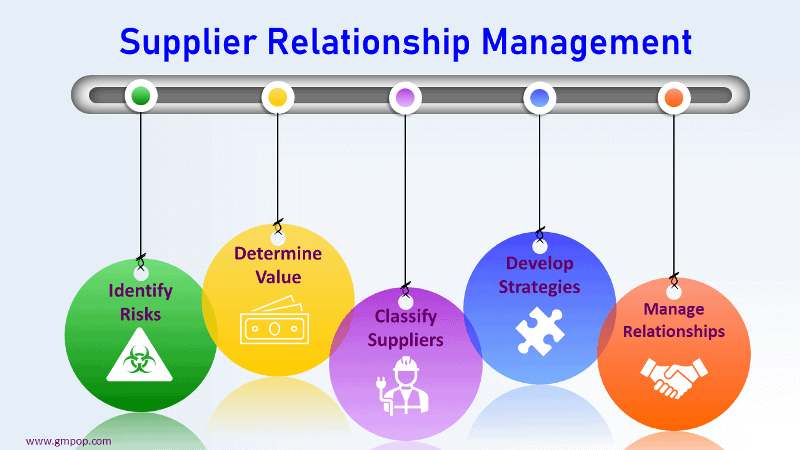

Packaging Materials shall be purchased from Approved Suppliers and received in the same manner as Raw Materials (RM). Testing and release requirements for these materials shall be defined by specifications and include, and not be limited to, dimensional tests.

Changes to the Process for Packaging Components by the Component Manufacturer shall be evaluated by the Site Quality Team to determine the potential impact on container closure integrity. The Site Quality Team shall consult, as necessary, with principals from, and not limited to, the following:

1. Regulatory Affairs (RA)

2. Site Production, and

3. Site Packaging Design and Development.

Changes to the container closure system, which require regulatory approval or notification shall be managed through the Product Change Request system. Failure to Meet the Established Container Closure Integrity Specifications shall result in a Quality Assurance Investigation.