Process validation guideline for formulated products

- Published on: Sep 05, 2023

What is process validation

As per cGMP, process validation means ensuring a specific process consistently produces medicine that meets quality standards.

If you manufacture pharmaceutical products, it is your duty to ensure that the products you make are safe, pure, and effective for patients.

In summary, process validation involves documenting the processing steps, verifying that each process performs as intended, testing the products to ensure they meet the specified specifications, and continuously improving quality.

Process validation for formulated products

Process validation must ensure that a process can repeatedly and reliably produce a formulated product of the required quality.

You should use information from R&D to identify the critical process parameters that need to be tested during process validation to ensure batch reproducibility.

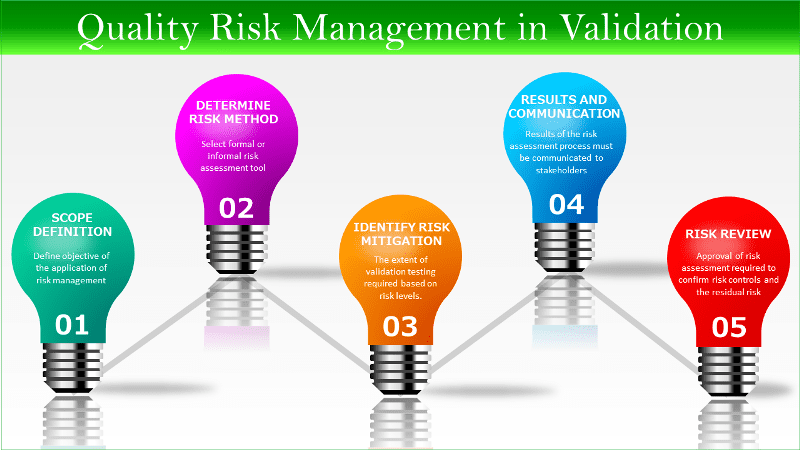

A risk assessment approach should be used to determine the scope and extent of validation.

A predefined number of validation batches (also called conformance batches) should be manufactured to demonstrate that, under normal conditions and defined ranges of operating parameters, the commercial scale process appears to make an acceptable product.

It should normally cover the manufacture of at least three consecutive batches of material.

Validation should be performed under conditions suitable for routine manufacture. The batch size should be the same as or representative of the intended commercial-scale batches.

Sampling and testing should be carried out to ensure compliance with the most stringent requirements.

Determining critical process parameters

The rationale for defining a process’s critical parameters should be documented, including the probable adverse consequences to be expected when critical process parameter ranges are not met.

Critical process parameters should be determined by a review of available historical data generated during development and manufacturing or by experimentation.

Each critical step is evaluated by observing potential critical process parameters’ effect on quality attributes.

This approach establishes the proven acceptable range (PAR), which states that process parameters can vary without an unacceptable impact on the acceptance criteria established for the critical quality attributes.

The normal operating range (NOR) should be within or equal to the PAR.

To determine the critical parameters, a documented Risk Assessment, such as comparing the margin between the NOR and the PAR, process capability analysis, or statistical evaluation, may be used.

A process step that includes one or more critical parameters should be considered critical.

240 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

Process validation protocol

The validation protocol contents should include or reference at least the following:

– The validation approach to be used (e.g., prospective, concurrent, matrixing, bracketing, retrospective), with justification for the approach chosen.

– Brief product description, including product name, dosage form, and strength where applicable.

– Master manufacturing instructions or Device Master Record (DMR) to be validated.

– Brief description of the process with a summary and process flow diagram of critical processing steps to be evaluated and critical parameters to be monitored.

– On-Line or In-Line Monitoring may be used instead of discrete sampling (e.g., to demonstrate homogeneity or acceptance criteria).

– Homogeneity, a key aspect of the validation protocol, should be demonstrated throughout the batch, when required, to [ensure uniformity and consistency in the product].

Acceptance criteria in process validation

The validation protocol for the formulated product must have clear and achievable acceptance criteria.

Typical acceptance criteria are:

– Acceptability (meeting established critical quality attributes and specifications).

– The number of consecutive successful validation batches/lots needed to show consistent process control.

– Equivalency to existing drug products (where applicable) compared to previously produced batches/lots (commercial, development, or bio-batches).

– Requirements to conduct homogeneity and hold time studies, if applicable.

– The sampling plan, including the type, amount, and number of samples, together with any special sampling or handling requirements.

– Critical process parameters and operating ranges, including justification for these Ranges.

– Calibration of any critical equipment used specifically for the validation studies (e.g., one-time studies on validation batches/lots using portable equipment, measuring equipment);

– Plan for the number of batches/lots to be put on stability, if any.

– Methods for recording and evaluating results (e.g., statistical analysis).

Why do you need three batches to validate?

To get a more accurate and unbiased representation of the validation model’s performance, your validation study needs at least three batches.

If you use one single batch during your validation study, it may not provide an accurate picture of the model’s performance, as the specific parameters and environments can influence the results in that batch.

By using at least three or more batches, the validation results are more likely to represent the model’s performance on unseen data.

Reiterate the benefits of using more than one validation sets if possible. This practice can significantly reduce the chance of overfitting and provide a more comprehensive understanding of the model’s performance.

Sampling plan during process validation

A sampling plan for the homogeneity study should be provided that justifies the number of individual locations and the number of samples to be taken from the product batch [e.g., for blend uniformity].

On completion of the process step, the bulk should be representatively sampled based on product type (e.g., aqueous solution or solid dosage), mixing container geometry, and process (e.g., mixing mechanism).

Additional sampling may also be performed upon completion of discrete critical steps.

Sampling should not impact the quality of the final bulk mixture. It should target areas of product in the equipment with the greatest potential for non-uniformity.

Representative samples should be drawn after critical process steps (e.g., freeze drying, filtering, blending).

Sampling plans should consider start-up requirements (e.g., line flushing or discard procedures), process control frequency (fill weight, hardness), line stops or interventions, and the final units.

When selecting specific tests, it is crucial to choose those that can effectively demonstrate the physical and/or chemical homogeneity of the product. This comprehensive evaluation is essential for ensuring the product’s uniformity.

The individual samples should meet the acceptance criteria defined for the homogeneity test(s).

240 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

Conclusion

The process validation of formulated products starts with a well-defined validation plan and protocol.

The process validation protocol outlines the steps to ensure that a pharmaceutical process consistently produces a formulated product meeting quality standards.

It begins by identifying critical process parameters through a risk assessment, considering potential adverse consequences if they are not met.

Historical data or experimentation helps determine critical process parameters, establishing the proven acceptable range (PAR) within which parameters can vary without impacting final product quality.

Validation is conducted under conditions mimicking routine manufacturing, with batch size representative of commercial scale.

Sampling and testing ensure compliance with stringent requirements, focusing on critical process steps.

The protocol includes validation approach justification, product description, process details, and acceptance criteria.

Homogeneity studies are conducted as needed, with sampling plans ensuring representative samples.

Tests demonstrate physical and chemical homogeneity, with individual samples meeting acceptance criteria.

On-line or in-line monitoring may substitute discrete sampling to demonstrate homogeneity or fulfillment of acceptance criteria.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

Computer system electronic record standard

Practice for Assigning Expiration Dates in Medicinal Products

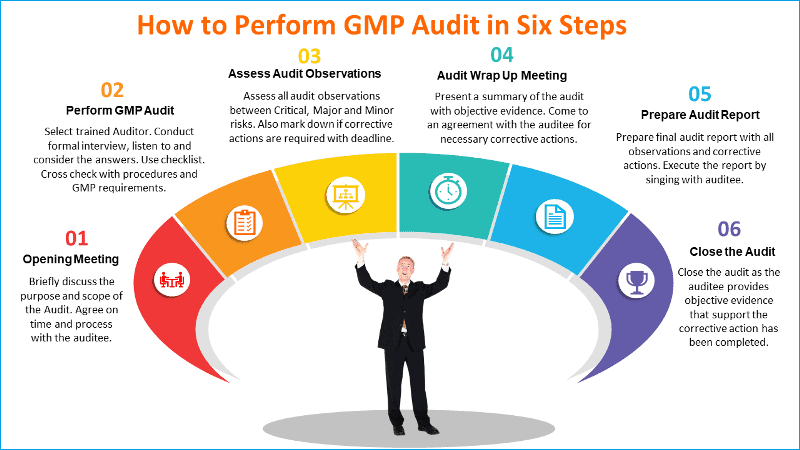

How to Perform GMP Audit in Six Steps