Raw Material Supplier Approval in GMP

- Published on: Oct 27, 2017

This article defines the process for identifying Suppliers to be audited and the process for conducting and documenting such audits and approving suppliers.

Disposable items, such as filters, filter cloths and drums used for storage of materials (non-product contact), sanitizing agents, regeneration materials and certain quality control lab Reagents are not included in the scope of this practice document.

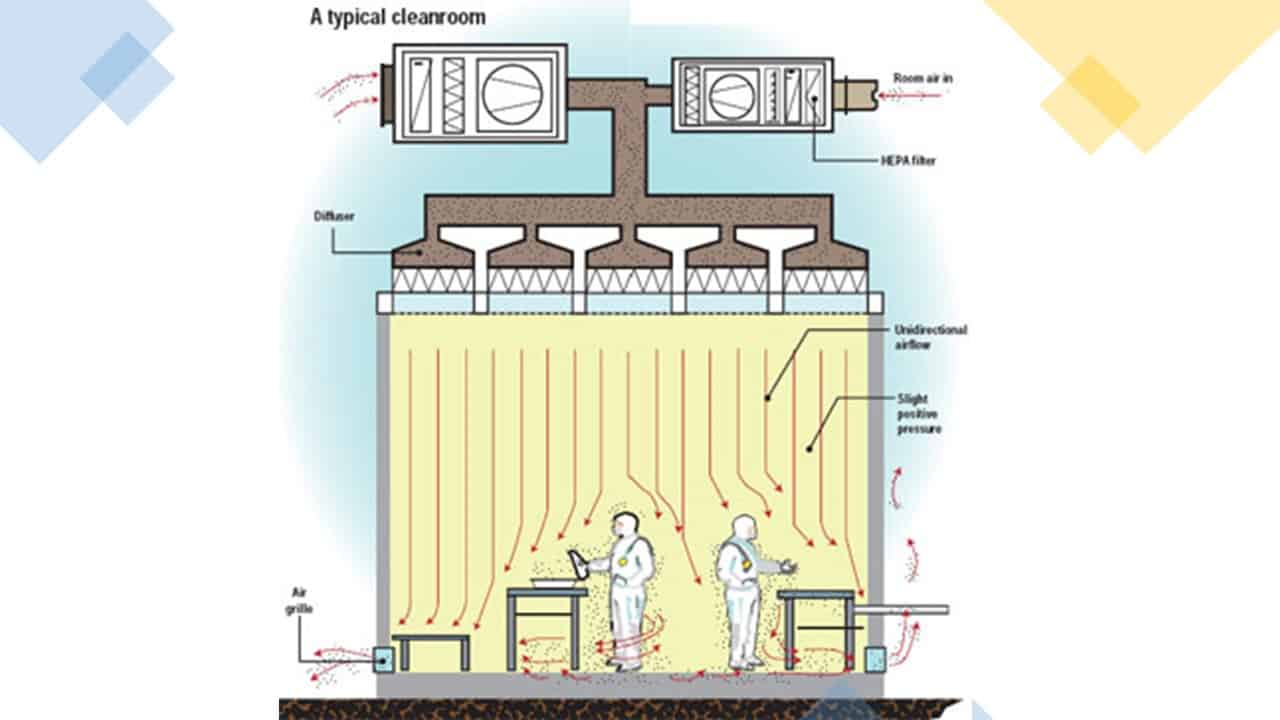

This practice applies to GMP production sites and operations responsible for purchasing production materials for use in Active Pharmaceutical Ingredients (API), Drug Products and Medical Devices.

Production Materials shall be purchased only from Approved or Conditionally Approved Suppliers.

Each Supplier will be assigned two classifications:

- Supplier Audit Rating, and

- Supplier Status.

Both classifications are specific with regard to manufacturing location(s) and production material concerned.

A Supplier Audit Rating shall be assigned as one of the three following categories and represents one of the measures used to determine whether a specific production material manufactured at specified location(s) may be purchased from the supplier:

- Acceptable Supplier -audit rating of a supplier which recommends that may continue current business, initiate new business, and may purchase additional similar product types (e.g., Magnesium Stearate vs. Sodium Stearate) without conducting additional audits;

- Conditionally Acceptable Supplier -audit rating of a supplier which recommends that may conduct business with the supplier, but withadditional testing requirements or other conditions, as specified by the Site Quality Team; or

- Unacceptable Supplier -audit rating of a supplier which recommends that should suspend current business and shall not initiate new businesswith the supplier.

A Supplier Status is a status assigned to a supplier to indicate whether a specific production material manufactured at a specific location may or may not be ordered from the supplier. There are three types of Supplier Status:

- Approved Supplier -supplier status that indicates production materials specified may be ordered from the supplier when manufactured at a specific location;

- Conditionally Approved Supplier – supplier status that indicates production materials specified may be ordered from the supplier when manufactured at a specific location only when certain conditions have been satisfied, as defined in the Supplier Audit Report, or as otherwise defined by Site Quality Team; and

- Unapproved Supplier -supplier status that indicates production materials specified may not be ordered from the supplier when manufactured at a specific location.

Two Types of Production Material Supplier Lists shall be maintained:

- Supplier Audit Master List, and

- Site Approved Supplier List.

The Site Quality Team shall be responsible for the following audit related activities:

- Review and issue Supplier Audit prioritization and schedules;

- Conduct Supplier Audit;

- Issue Supplier Audit Report;

- Assign Supplier Audit Rating;

- Send copy of the Supplier Audit Report which includes the Supplier Audit Rating to:

- Quality Audits Team,

- Representative of the supplier audited,

- Site Quality Team;

- Site Leadership Team; and

- Site Procurement team at all Sites involved with the Supplier;

- Follow up on any Supplier Audit action items or findings;

- Update in the Supplier Audit Master List (Supplier Audit Database) the manufacturer and location of materials procured and the user Sites that procure them; and

- Determine if an approved supplier of a specific production material requires another audit before supplying a similar and/or different product type to.