Cleaning Validation for Active Pharmaceutical Ingredients

- Published on: Oct 27, 2017

INTRODUCTION

A cleaning validation program must be in place to establish documented evidence that the cleaning processes will perform consistently, ensuring that the Active Pharmaceutical Ingredients (APIs) produced will meet expectations for purity, identity, safety, and quality.

Cleaning procedures are typically shown to be adequate and appropriate in two ways, verification and validation. While often used interchangeably, the two terms are not the same.

Verification of Cleanliness: Following each cleanup, the equipment is typically sampled and assayed using validated sampling and assay methods. If the assay results indicate that the level of residuals is below the pre-determined acceptable quality limit, the equipment is considered “clean”. Visual inspection, when possible, is also required to verify cleanliness.

Validation of Cleaning Procedure: Validation establishes documented evidence that a cleaning procedure, when executed exactly as written, will consistently perform as expected. Validation involves establishing a pre-defined written protocol which describes the strategy to demonstrate the consistency of the cleaning procedure.

STANDARD REQUIREMENTS

A. Scope

1. Written procedures shall be established for cleaning of equipment and its subsequent release for use in manufacturing of intermediates and APIs.

2. Analytical verification test methods used to verify equipment cleanliness and release equipment for intermediate or API production must be validated.

3. Non-dedicated equipment shall be cleaned between production of different materials to prevent cross-contamination.

4. Where equipment is assigned to continuous production (dedicated equipment) or campaign production of successive batches of the same intermediate or API, equipment shall be cleaned at appropriate intervals to prevent build-up and carry-over of contaminants (e.g. degradants). The maximum number of cycles and/or time between cleanings shall be established.

5. At a minimum, cleaning procedures shall be validated for all product contact equipment that is used to produce one or more final APIs. This requirement also applies to dedicated equipment.

6. These requirements apply to APIs produced from chemical synthesis, fermentation operations, and biotechnology processes.

7. For clinical APIs produced in commercial Production equipment, the equipment must be verified as clean before and after the clinical API production. Cleaning validation typically requires three consecutive successful cleanups. Cleaning validation is typically not required to be initiated until the API enters the final manufacturing process (typically Phase III or later). This is typically a PAI-readiness activity.

8. Cleaning procedures, verification and Master Validation Plans must be documented. These documents must be approved by QA.

B. Cleaning

1. Cleaning procedures must specify:

(a) Cleaning agent identification, volumes, concentration (as appropriate), method of application, contact time, and rinsing. For API manufacturing, cleaning agents will often be organic solvents.

(b) Removal of cleaning agents. Solvents are typically removed by heating/vacuum drying and/or rinsing the equipment with the next processing solvent to be charged. Equipment should not be left containing standing water due to potential microbial proliferation.

(c) Routine verification to release clean product contact equipment. The minimum requirement is visual inspection. Verification of large, closed, multipurpose equipment typically also involves rinse sampling and testing for product residue. This verification is typically performed after each campaign.

(d) The type of cleaning being performed (i.e. manual, automated)

(e) The cleaning parameters such as temperatures, reflux, recycle, and distillation times.

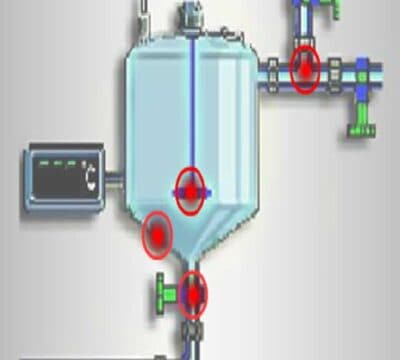

(f) Disassembly and manual cleaning of deadlegs or difficult to clean areas, as appropriate.

(g) The types of cleaning utensils used (i.e. brushes, cloths, swabs)

(h) Sampling locations (i.e. rinse sample ports, swab sites, visual inspection sites)

(i) Labeling of the equipment with cleaning status

(j) Storage of the clean equipment (closed, capped, covered, protected from potential contamination)

2. A system must be in place to quarantine the equipment until verification of the clean equipment is complete.

3. Equipment shall be evaluated for cleanability. Consideration should be given to modify equipment configurations, as appropriate, to remove and reduce difficult to clean areas such as product contact piping deadlegs. Localized areas where residue could build-up and which could go undetected by sampling and/or analysis should be identified.

4. The length of the campaign shall be considered since longer campaigns may cause the equipment to be more difficult to clean. In many cases, the length of the campaign will not call into question the effectiveness of the cleaning since the compounds do not become more difficult to clean and cleaning verification is performed after each clean-up.

5. As residues are allowed to stand in equipment, solvent evaporation may make them more difficult to remove. A time limit between last use of the equipment and initiation of the cleanup must be considered. If a time limit is not imposed, a rationale for omission of such a limit must be documented.

6. For a given workcenter, cleaning procedures may be consolidated, as appropriate, to allow for the use of indicator compounds. The indicator concept allows products to be grouped based upon use of the same cleaning procedure, use of the same equipment, and common structural similarity or other functionality. The cleaning of the most difficult materials (indicators) from this group may be validated and the results applied to the group as a whole. This approach can significantly reduce the validation effort for a given workcenter.

210 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

C. Verification Sampling and Testing

1. Two sampling methods are commonly used, and have a direct impact on the analytical method selected for use:

Swab Sampling:

This method includes the use of swabbing material, often saturated with solvent, to physically sample the equipment surface. The swab is typically extracted and the residue quantitated with an analytical method. This method theoretically provides a direct measurement of the surface cleanliness for the specified area sampled. This method may therefore be technique dependent. Swab sampling does not allow sampling of the complete surface for large equipment. It also does not allow for sampling of inaccessible areas of the equipment which may be difficult to clean. Swab sampling is generally applicable to smaller, open or accessible equipment.

Rinse Sampling:

This method involves the use of a known volume of solvent to rinse the equipment surface. A sample of the solvent is collected and analyzed by an analytical method. The solubility of the residue in the rinse solvent must be considered. The solvent must be chosen such that it has a relatively high recovery for the residue of interest. The application of the solvent rinse must be such that the rinse contacts all of the product contact surface area. This method can provide a measurement of the entire product contact surface area and may be used for inaccessible areas of the equipment. It is for this reason that rinse sampling is the most common sampling method typically utilized in API manufacturing.

2. Typically, rinse sampling is routinely used to verify cleanliness of large, closed, inaccessible, multipurpose work-centers, even after the validation studies are complete.

3. Swab sampling is often used in combination with rinse sampling during the validation studies.

4. Validation of sampling methods must include:

(a) Solubility studies of the residue(s) of interest in rinse solvents

(b) Consideration of swab material for potential assay interferences

(c) Stability studies on the storage conditions for the swab or rinse samples.

(d) Recovery studies from a material that is representative of the production equipment. Recoveries of 50% or greater are considered acceptable.

5. Validation of test methods must be completed. Consideration should be given to the use of Limit (pass/fail) test methods. Typical test method validation for these types of Limits tests include:

(a) Specificity

(b) Detection Limit

(c) Robustness

D. Limits

1. Drug Residue

(a) A cleaning verification limit may be calculated for each cleanup, considering the material being cleaned out and the next material to be produced. Alternatively, one limit may be calculated for all materials produced in a given workcenter by considering the worst case variables for the calculation.

(b) A limit should be calculated for the equipment train in a defined workcenter. If a limit is calculated for each piece of equipment in a workcenter then a sum limit should be established for the workcenter. If this approach is not used, then a rationale for an alternate approach must be documented.

(c) Three types of calculations exist for comparison and determination of limits: dose calculation, toxicity calculation, and weight percent calculation. Visual inspection must also be utilized when it is possible to visually inspect at least portions of the workcenter.

(d) Safety Factors must be 100 or greater since this is consistent with API industry standard.

(e) Dose, toxicity, and weight percent calculations must be performed when possible. Since intermediates may not have dose and toxicity information available, a workcenter producing strictly intermediates may have a limit based solely upon a weight percent calculation. When it is possible to calculate dose, toxicity, and weight percent limits, the three limits must be compared and the most conservative limit chosen for the workcenter. Typical limits are established by the following:

Dose Calculation: MAC = (STD) x (BS) / (SF) x (LWSD)

Where:

MAC =Maximum Allowable Carryover (Limit)

STD = Smallest Therapeutic Dose of any API produced in the workcenter

BS = Batch Size of largest dose API produced in the workcenter

SF = Safety Factor

LWSD = Largest Single Daily Dose of any API produced in the workcenter

Toxicity Calculation: MAC = (NOEL) x 50 kg x BS / (SF) x (LWSD)

Where:

MAC = Maximum Allowable Carryover (Limit)

NOEL = No Observed Effect Level = LD50 x 5 x 10-4

BS = Batch Size of largest dose API produced in the workcenter

SF =Safety Factor

LWSD = Largest Single Daily Dose of any API produced in the workcenter

50 kg = Average human body weight

Weight Percent Calculation: NMT 10 ppm (NMT 0.001%) carryover of one material into the next material produced. A worst-case calculation may be performed using the smallest lot (kg) produced in the workcenter. For workcenters producing small lots (less than 100 kg), the Weight Percent limit may be raised to NMT 100 ppm. This is consistent with API industry standard and is considered to be practical, achievable, and verifiable.

Visual Inspection: No quantity of residue will be visible on the equipment after cleaning procedures are performed.

2. Cleaning Agent

(a) Cleaning agent (including solvents) limits must be stated, or a rationale provided as to why they are not required. For example, if the cleaning agent is a solvent, which is dried from the equipment after cleaning or used in the next processing step, solvent limits are generally not required.

(b) The residue limit for commercial cleaning agents, such as detergents, on product contact sites is no visible residue. An analytical test Weight Percent limit of not more than 10 ppm (0.001%) carryover into the next batch processed is also required unless another limit is required or approved by medical or toxicological expertise. Sampling and assay methods should be developed and validated to measure cleaning agent residues.

3. Other

(a) Other residues should be considered on a case-by-case basis when setting limits for a given workcenter and product. Some processes may leave unwanted by-products, reagents, or precursors for which limits may be required.

(b) Particulate limits may also be required depending upon the product and the equipment.

(c) Dedicated equipment requires a minimum of visual inspection to verify equipment cleanliness. If adequate visual inspection is not possible, then rinse sampling is needed on at least an audit basis.

(d) For aseptically produced or crystallized APIs destined for sterile drug products, microbiological and endotoxin cleaning limits shall be considered, especially if water is the last solvent used in the cleaning/rinsing process. For aseptically produced or crystallized APIs, direct product-contact surfaces used during the aseptic processing must be sterilized utilizing validated sterilization methods.

(e) For non-aseptically crystallized or produced APIs, there is generally no requirement for validation of cleaning methods as they relate to microbiological “cleanliness.” Specific cases may warrant evaluation of the cleaning methods for microbiological cleaning effectiveness. However, after cleaning, equipment should be handled and stored in a manner that does not allow for microbial proliferation (i.e. equipment should be dried after cleaning and before storage).

E. Cleaning Validation Plan, Protocols, and Reports

1. Validation Plan

(a) A written plan, with prioritization and timelines, must be available which outlines the cleaning validation program. This plan must have a periodic review period of 1-3 years.

(b) This plan should include or reference:

- Introduction (Purpose, Site Scope, Limitations)

- Site Listing of Processes or Equipment to be Qualified

- Validation Requirements and Approach

- Typical Critical Requirements

- References and Procedures

- Change Control and Document Control

- Timeline, Resources and Responsibilities

- Documentation and Approvals

- Document Preparation and Location

2. Cleaning Validation Protocols

A Cleaning Validation Protocol must be prepared for each validation conducted and must contain:

- Approval Page

- Description of Process, Equipment, Cleaning Procedure, and Verification

- Scope of Validation (material or equipment grouping, indicators, etc.)

- Acceptable Residual Limit(s) (residual type, calculations & rationale)

- Acceptance Criteria (number of cleanups, equipment disassembly, documentation, etc.)

- Validation Results Section to collect data

- Supporting Documentation & References

3. In general, three consecutive successful clean-ups are required to satisfy validation requirements.

4. Additional equipment disassembly, visual inspection, and swab sampling must be considered for the validation cleanups. This disassembly and visual inspection is typically above and beyond that normally performed during a routine cleanup.

5. Cleaning Validation Reports

A Cleaning Validation Report must be prepared for each validation conducted and must contain:

- Approval Page

- Summary and Conclusions

- Description of Deviations & Corrective Actions

- Recommendations

- Results

6. Cleaning Validation Plans, Protocols and Reports must be reviewed and approved by QA.

F. Deviations and Cleaning Failures

Deviations and cleaning verification failures must be investigated and documented. The documentation must include:

- Validation protocol number (reference)

- Deviation report number

- Equipment, location and product name

- Description and scope of incident

- Root cause(s) and corrective action(s)

- Impact on the validation

- Impact on product

G. Change Control

If changes are made they must be evaluated to determine if they impact the cleanability of the equipment, the cleaning records, the verification sampling or test methods, or the cleaning validation. Changes must be documented and receive appropriate review and approval. Examples of changes which may impact cleaning of a given workcenter include:

- Introduction of a new product

- Introduction of a new piece of equipment

- Significant changes to equipment or piping surface area (greater than about 10%)

- Changes in smallest lot size of any product produced in the workcenter, as this may affect the limits calculations.

- Changes impacting cleanability of equipment (piping configuration changes, changes in sprayball placement, etc)

- Changes in cleaning procedures (cleaning agent (solvent) identification or volumes, reflux times, etc.)

- Modification of sampling procedures or locations

- Modification of verification test methods or limits

Related Posts

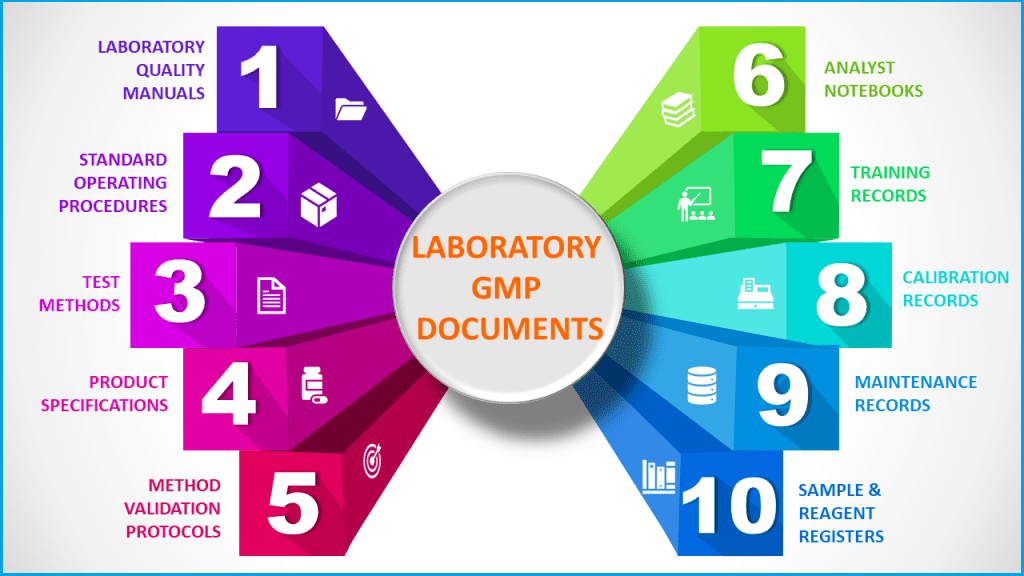

Typical GMP documentation in a quality control laboratory

API Packaging and Labeling Guidelines

Laboratory Waste Disposal Procedure at a GMP Site