Concept of process validation in pharmaceutical industry

- Kazi

- Last modified: March 13, 2025

What is process validation in pharmaceutical industry?

According to cGMP, process validation is “Establishing documented evidence which provides a high degree of assurance that a specific process is capable of consistently producing a product meeting its pre-determined specifications and quality attributes.”

Process validation is a critical concept in the pharmaceutical industry. Successful validation activities ensure that processes and products meet the required quality standards.

The validation process involves identifying and documenting the specific requirements established to manufacture the product and then demonstrating that the product consistently meets those requirements.

This includes testing the process parameters relevant to making the product and verifying that the process is free from defects and functions as intended.

Additionally, validation includes continuous monitoring and re-evaluation to ensure that manufactured products comply with quality attributes and the processes involved in making those products comply with established requirements.

In this article, you will learn about process validation, different validation approaches, critical areas of operations where validation is required, and how to conduct a successful validation study.

By implementing robust validation protocols, companies can ensure that their products are safe, effective, pure, and of the highest quality.

Table of Contents

A scenario where validation is required

Let’s consider the manufacturing process for tablets, a common pharmaceutical dosage form.

Here’s an overview of the manufacturing processing steps where validation is required:

1. Development of tablet formulation:

Tablet formulation includes active pharmaceutical ingredients (APIs), excipients, and other necessary components.

You must ensure the formulation meets efficacy, stability, and safety requirements through validation studies.

2. Raw material procurement and testing:

You should only procure APIs, excipients, and packaging materials from approved suppliers.

Each batch of raw materials undergoes testing for identity, purity, potency, and other quality attributes to ensure compliance with specifications.

3. Blending and granulation:

The formulation ingredients are blended and granulated to form uniform granules.

The granulation process should be validated to ensure that the powder blend’s flow properties, compressibility, and content uniformity meet acceptance criteria to ensure high-quality tablets.

4. Tablet compression:

The granules are then compressed into tablets using tablet compression machines.

During validation, you should produce evidence that the compression machine can transform the granules into tablets of the desired size, shape, and hardness.

5. Packaging:

Finished tablets are packaged into bottles, blisters, or sachets.

Through validation study, you can generate assurance that the packaging materials are fit for purpose. The tablet strips will meet stability requirements and patient convenience.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

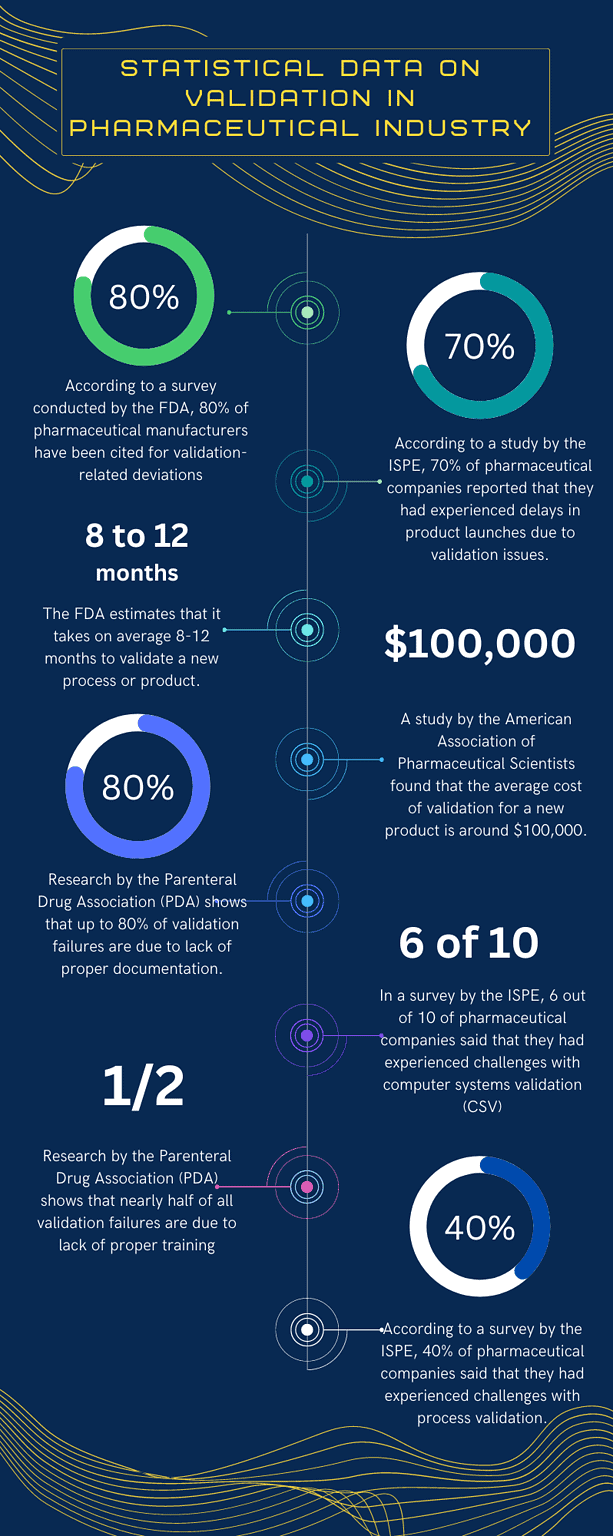

Statistical data on process validation

i. According to a survey by the FDA, 80% of manufacturers have been cited for validation-related deviations.

ii. According to a study by the ISPE, 70% of companies reported experiencing delays in product launches due to validation issues.

iii. The FDA estimates that it takes, on average, 8-12 months to validate a new process or product.

iv. A study by the American Association of Pharmaceutical Scientists (AAPS) found that the average cost of validation for a new product is around $100,000.

v. Research by the Parenteral Drug Association (PDA) shows that up to 80% of validation failures are due to a lack of proper documentation.

vi. In a survey by the International Society for Pharmaceutical Engineering (ISPE), 60% of companies said they had experienced challenges with computer systems validation (CSV).

vii. Research by the Parenteral Drug Association (PDA) shows that up to 50% of validation failures are due to a lack of proper training.

viii. According to a survey by the ISPE, 40% of companies said they had experienced challenges with process validation.

What process validation approaches are common?

There is no one-size-fits-all approach to process validation.

The optimum validation approach you may choose depends on many factors, such as:

i. The types of products your site is licensed to manufacture.

ii. The chemistry and risk profiles of the therapeutic agents you can process.

iii. The complexity of unit operations, processes, and systems you employ during manufacturing and testing.

iv. You might have generated Empirical data, evidence, and experience throughout the process lifecycle.

v. The age and modernity of your facilities and equipment.

vi. The strength of environmental controls you have implemented surrounding your processes.

vii. How well-trained are your manufacturing staff in good manufacturing practices?

These are some of the highlights you’ll need to consider while selecting the validation approach.

Also, you can not ignore the regulatory requirements and guidelines relevant to your products.

Whichever approach you choose, you must build strong justifications and supporting evidence acceptable to your local regulatory authorities.

3 stages of process validation

It is recommended that process validation be performed in three stages.

1. Process design stage:

At this stage, you should define your manufacturing process based on knowledge gained from development and scale-up activities.

2. Process qualification stage:

During this stage, you should evaluate the process design to ensure the reproducibility of commercial manufacturing. You must assess whether the designed process can always produce products with the desired quality attributes.

3. Continued process verification stage:

This is the routine production stage. During routine production you have to generate ongoing assurance that the routine production process remains in a state of control.

As a manufacturer, you are responsible for achieving high confidence in your production process before releasing batches for commercial distribution. This assurance is based on objective evidence gathered from pilot-scale, commercial-scale, and laboratory research.

Identifying the causes of variation in the process and its existence and effect is critical, and then implementing control mechanisms appropriate for the risks involved.

Process control requires constant attention to detail to adjust for personnel, equipment, materials, and procedure modifications.

Establish programs to collect and analyze data to assess process control and find improvement areas.

In addition to prior manufacturing experience, you can utilize the original development and qualifying efforts, even for legacy items.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Types of process validation

To keep it simple, three types of process validation approaches are prevalent in the pharmaceutical industry.

1. Prospective validation

In this approach, you must establish documented evidence that a piece of equipment/process or system will do what it purports to do, based upon a pre-planned series of scientific tests as defined in the validation plan.

Could you perform a prospective validation before you can use a process, method, or system to put into routine use?

In this validation approach, you must prepare a project plan and a well-designed validation protocol with specific tests, parameters, and acceptance criteria.

Conduct the tests, analyze the data, and present the final results to demonstrate that the processes and systems are acceptable in accuracy, precision, reproducibility, and robustness.

2. Concurrent validation

You may select this approach when an existing process can be shown to be in a “state of control” by applying tests on samples at strategic points throughout and at the end of the process.

All data is collected concurrently with the implementation of the process until sufficient information is available to demonstrate process reproducibility.

Suppose you want to concurrently validate an automatic filling machine that has been operating for some time.

During this validation, you need to list the key process parameters, such as approved containers (e.g., tube, ampule, etc.), fill volume and weight accuracy, sealing integrity, and effectiveness of in-process controls.

You can conduct your tests over several routine batches. Collate and analyze all the data and outcomes to demonstrate that the filling machine performs robustly as intended.

3. Retrospective validation

In this approach, you must establish documented evidence that a process does what it purports to do based on a review and analysis of historical data and process performance.

In retrospective validation, you should methodically collect historical data and records.

Please take a look at the empirical data and documented performance to make sure that your process produces precise, accurate, specific, and reproducible outcomes.

Regulatory requirements for process validation

If you are in a business to manufacture and sell medicinal products for human use, your products must be registered with your local regulatory authority with sufficient evidence that they are safe, pure, effective, and traceable.

It is a regulatory requirement that you produce evidence-based determinations that the process validation stages you have undertaken are adequate to prove that your processes consistently produce a product of the desired level.

According to the FDA, Process validation for drugs, both finished pharmaceuticals and components, is mandated by law under section 501(a)(2)(B) of the Act.

This requires adherence to current good manufacturing practice (CGMP) regulations outlined in 21 CFR parts 210 and 211.

CGMP regulations necessitate that manufacturing processes be planned and monitored to ensure consistency and reliability in meeting quality standards.

Process validation, as outlined in § 211.100(a), requires written procedures for production and process control to ensure product attributes like identity, strength, quality, and purity.

Other CGMP regulations detail aspects of validation, such as

i. Sampling and testing of in-process materials,

ii. Establishment of in-process specifications consistent with final product specifications and

iii. Ongoing product quality and manufacturing experience review to determine necessary process changes.

iv. Facility and equipment requirements are specified to ensure proper operations and performance.

In summary, CGMP regulations guarantee that manufacturing processes produce products that meet quality requirements consistently and reliably.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Which processes need to be validated?

In general, you must formally validate all process steps, production equipment, cleaning methods, testing methods, computer systems, environment, facilities, and utilities that are directly used to manufacture sterile and non-sterile products.

If you have major packaging equipment and processing facilities, those must be validated. This validation is relatively less comprehensive.

All ancillary systems that do not directly impact product quality should be qualified using technical documentation of the extent of the system and how it operates.

Equipment used in pharmaceutical manufacturing processes can range from basic balances to sophisticated and automated process control and monitoring systems (e.g., PLC, SCADA, CIP, etc.)

Since the processes are so different in complexity, it is not practical for you to use a single set of principles to support the same level of validation program. It would also be incorrect from a scientific standpoint.

Suppose you routinely use multiple dedicated software applications with many functionalities. Some you have bought as commercial off-the-shelf and have minimal impact on production operations.

On the other hand, some are specially customized, installed, and configured, directly impacting your processes and product quality.

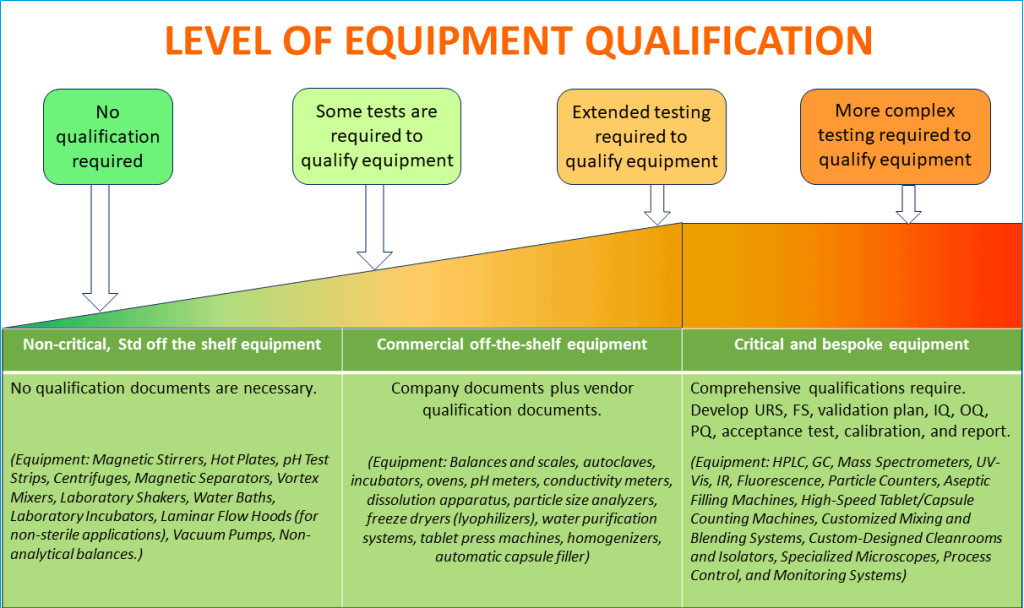

In such case, you should conduct a risk-based categorization of all processes and systems and list them between,

– Non-Critical

– Commercial off the shelf (COTS)

– Critical, and

– Bespoke

When determining which equipment or process needs validation, follow the GAMP (Good Automated Manufacturing Practice) categorization standards created by the International Society for Pharmaceutical Engineering (ISPE).

GAMP offers a framework for validating automated systems based on equipment criticality.

GAMP categorizes software and hardware according to their complexity, which helps determine how much validation work is necessary.

Follow the diagram below to decide on the extent of necessary validation activities based on the product risk and criticality of equipment operation on products.

Pharmaceutical areas to include in process validation study

You should include the following products, processes, facilities, utilities, and computerized systems in your validation plan.

– Semi-solid drug products

– Oral solid dosage forms

– Solutions and suspensions

– Metered dose inhalers

– Dry powder inhalers

– Sterile drug products and medical devices including injection devices (i.e., syringes, pen injectors) etc.

– Manufacturing processes

– Filling and packaging proceses

– Personnel and material flow

– Cleaning procedures

– Testing equipment

– Raw/purified steam

– Purified water

– Compressed Air

– Air conditioning system

– Vacuum

– Power supply

– Lighting

– Cooling water

– Waste etc.

– Computerized Systems Design

– Information system (i.e. PLC, SCADA, LIMS)

– Laboratory automated equipment,

– Manufacturing automated equipment

– Electronic records etc.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Process validation examples in pharmaceutical

As per the local and international GMP requirements, when you adopt a new manufacturing formula or method of preparation, you must take the necessary steps to show that it is suitable for routine processing.

Process validation refers to the product’s performance under predetermined process conditions, demonstrating that the process consistently yields a product of the required quality.

Validation ensures that manufacturing can produce a consistent, high-quality product.

For example, if your site is licensed to manufacture, test, and release Paracetamol tablets with a label claim of 500mg + 2%.

All relevant processes and systems used to manufacture those tablets must be validated to demonstrate that all tablets fall between 490mg and 510mg.

If your processes fail to produce Paracetamol tablets within those parameters consistently, the validation of your processes will be questionable.

Typical process validation examples include:

– Validation of processing steps for formulated products.

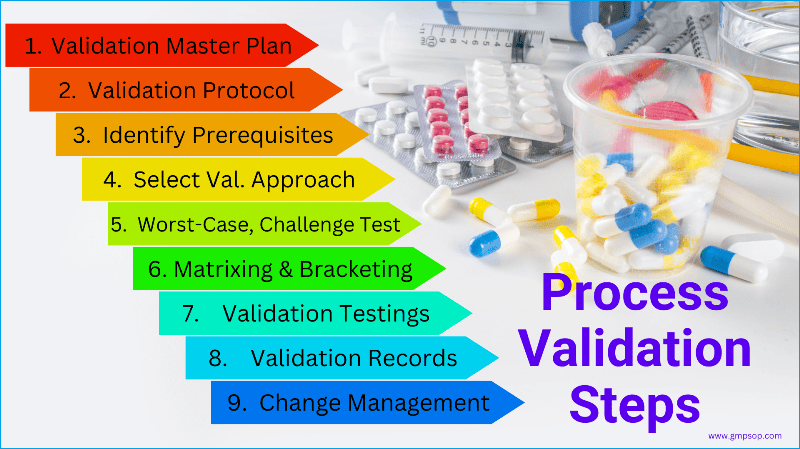

1. Process validation for formulated products

The process validation of formulated products (e.g., tablets, capsules, ointments, etc.) starts with a well-defined validation plan and protocol.

The validation protocol outlines the steps to ensure the process consistently produces a formulated product meeting quality standards.

It begins by identifying critical process steps and parameters (e.g., blending, granulating, tableting, etc.), conducting validation risk assessment, and considering potential adverse consequences if they are not met.

We have prepared some essential steps relevant to most process validation activities for formulated products.

a. Develop a validation master plan.

For more complex validation activities, a validation master plan, VMP, should be produced to describe the approach for each validation element.

A VMP is a strategic document that must be approved early in the project, and the scope of the elements needs to be validated.

b. Prepare validation protocol.

After you describe the elements in the validation master plan, define validation requirements for those elements in the validation protocol.

For example, qualified and calibrated facilities, systems, services, equipment, and validated testing methods.

The validation protocol should include, but not be limited to, the following:

– Detailed objectives.

– Process description.

– List of products/product strengths.

– List of processes, facilities, systems, and equipment to use.

– Summary of critical parameters and activities to evaluate.

– Number and identity of runs/batches.

– Release specification/s and list of analytical methods.

– Acceptance criteria.

– Proposed in-process controls.

– Additional testing to be carried out.

– Sampling plan and testing procedures.

– Methods for recording and evaluating results.

– Functions and responsibilities.

– Proposed timetable.

c. Identify prerequisites for process validation.

Prerequisites for process validation include, and are not limited to, the following:

– Approved master formulation, master manufacturing process instructions, and applicable standard operating procedures (SOP).

– Identified critical process parameters and critical quality attributes.

– Qualified equipment – facilities, utilities, and Computerized Systems.

– Qualified or validated supporting processes that may affect validation (e.g., Filtration, inspection, sterilization, media fills.

– Calibration of critical instruments.

– Approved specifications for finished products, raw materials, and components.

– Established in-process controls (IPC) and their decision criteria.

– Validated test methods will be required to test and release products.

– Qualified personnel will manufacture the validation batches.

d. Select validation approach

As we described earlier, the validation can be prospective, concurrent, or retrospective, depending on when it is performed concerning production.

Prospective validation must be the default method or approach for new or modified processes.

The validation protocol and the VMP (if applicable) must document the rationale and justification for using a concurrent or retrospective validation approach.

e. Worst-case and challenge tests

The process should be challenged by deliberate changes to demonstrate its robustness and define its tolerance limits.

In challenging a process to assess its adequacy, the conditions should simulate those that could be encountered during actual production.

These tests should be repeated to ensure that the results are meaningful and consistent.

Such worst-case or challenge tests should preferably be performed before manufacturing validation batches.

Typically, they are done during a validation program’s operational or performance qualification stage.

f. Determine matrixing or family approach

The general principle is to validate a manufacturing process, and the “same” process can typically be used for several related products.

Rather than developing a plan for each product manufactured by a process, you should develop a plan for that process instead.

Two general principles could be applied.

i. A “Matrix approach” generally means a plan to conduct validation on different strengths of the same product.

ii. A “Family approach” describes a plan to conduct validation on different but similar products.

Either approach must demonstrate that the process is consistent for all the strengths of products involved.

The plan should be designed to evaluate all likely sources of variation in the products manufactured by the process.

Each plan should be evaluated on a case-by-case basis.

This approach would not be applicable for significant differences in equipment or process, and each strength or product would need to be validated separately.

g. Perform validation testing

Validation tests are conducted under conditions mimicking routine manufacturing, with batch size representative of commercial scale.

Sampling and testing ensure compliance with stringent requirements, focusing on critical process steps.

Homogeneity studies are conducted as needed, with sampling plans ensuring representative samples.

Tests demonstrate physical and chemical homogeneity, with individual samples meeting acceptance criteria.

On-line or in-line monitoring may substitute discrete sampling to demonstrate homogeneity or fulfillment of acceptance criteria.

h. Validation Documentation

All documentation and raw data generated during validation activities are considered GMP documentation for retention/archiving purposes. It must be retained in a manner that permits traceability and ensures that it is readily retrievable.

We have provided a detailed list of validation documentation in the later section of the article.

i. Manage changes

You must document and manage all changes that may affect product quality and reproducibility. You must evaluate the likely impact on the process or product due to the changes.

Determine whether the change is major or minor and its impact on the validation status and stability testing.

Why do you need three batches for validation?

Your validation study needs at least three batches to provide a more accurate and unbiased representation of the validation model’s performance.

If you use a single batch during your validation study, it may not provide an accurate picture of the process’s performance, as the specific parameters and environments can influence the results of that batch.

When you use multiple batches, the validation results are more likely to represent the process performance on unseen data.

Additionally, more than one validation set should be used to reduce the chance of overfitting and give a better sense of the process’s performance.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

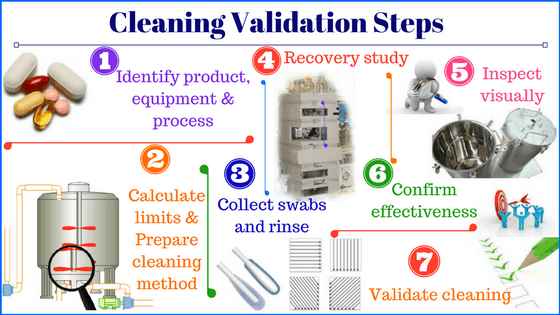

2. Process validation Vs. Cleaning validation?

Cleaning validation is indeed part of process validation. Sometimes, cleaning validation can be performed alongside process validation.

You can also prefer to conduct cleaning validation independently.

Cleaning is the removal of visible and microscopic contamination by dirt, extraneous matter, or product residues by mechanical or physical means.

The purpose of cleaning validation is to provide documented evidence that the cleaning processes used in a manufacturing facility effectively remove residues from a previous batch, cleaning agents, or microbial contamination below pre-established maximum allowable carryover limits.

The goal of cleaning validation is to ensure that the facility and equipment are clean and free from contamination, which can impact the quality of your products.

Evaluation of the cleaning procedure’s effectiveness involves sampling a cleaned and sanitized surface.

Then, test those samples to determine whether the level of product residues, cleaning agent residues, and bacterial contamination is below a pre-defined maximum allowable carryover limit before the next batch commences.

The term cleaning validation is to be used to describe the analytical investigation of a cleaning procedure. The cleaning validation protocols should provide a rationale for “worst-case” products.

The protocol should explain how the acceptance criteria, chemical and microbial specifications, limits of detection, and sampling methods were developed.

You can read our article “Equipment Cleaning in Pharmaceutical” to explore cleaning validation further.

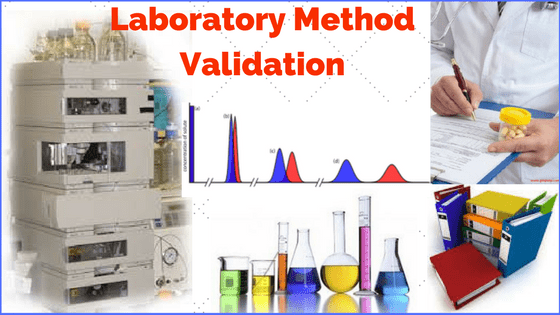

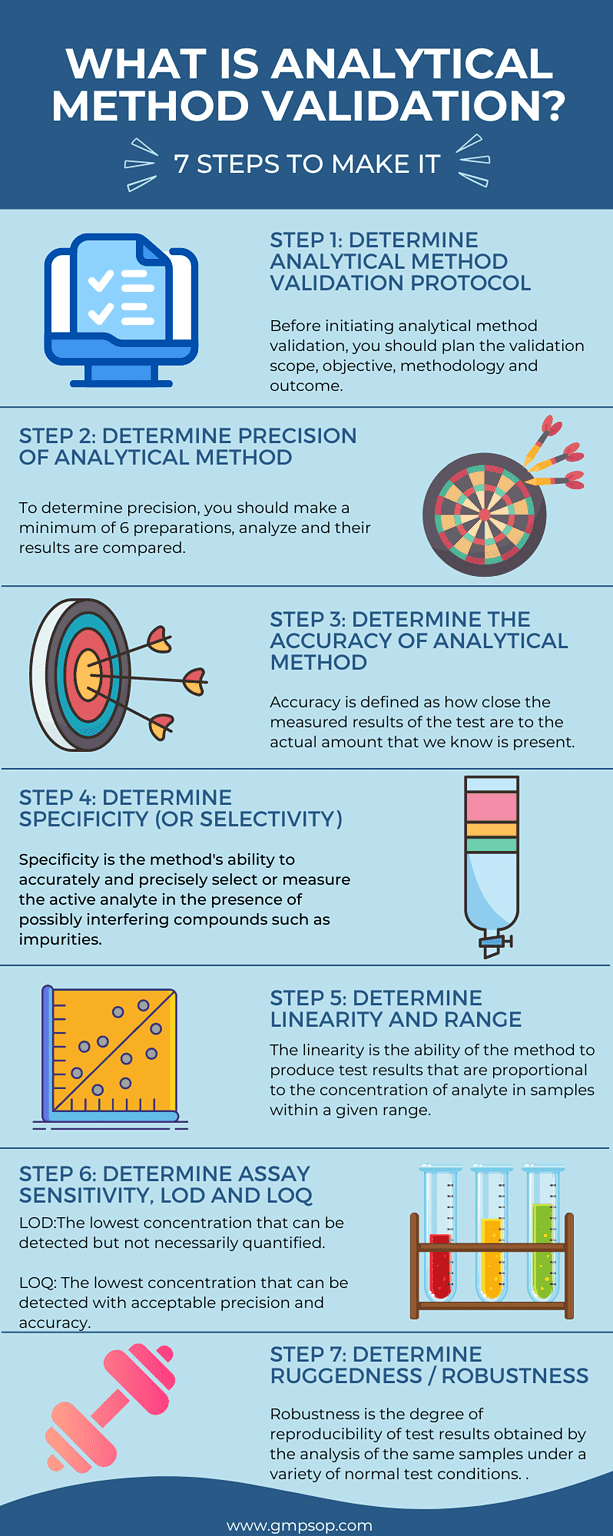

3. Process validation Vs. Method validation?

Analytical method validation is closely related to process validation but is typically carried out separately.

Analytical method validation, also called methodology or test method validation, involves demonstrating that the analytical methods used to test the quality of your product are accurate, reliable, and reproducible.

This is critical for ensuring the quality and safety of your products.

When you develop your test methods in-house, the method validation process provides more than documented evidence of accuracy, robustness, effectiveness, reproducibility, and repeatability.

It also allows you to fine-tune and optimize your methods, leading to better results and product quality assurance.

The validation protocols should reference background documentation relating to the rationale for determining limits of detection (LOD) and method sensitivity.

Method validation study includes:

– Identification and evaluation of the critical parameters of the analytical methods,

– Perform method validation studies,

– Document & evaluate the results.

To complete an analytical method validation, you will need to validate all or a combination of the following parameters:

– Precision, repeatability, intermediate precision.

– Method accuracy

– Sensitivity: Limit of detection (LOD)

– Sensitivity: Limit of quantitation (LOQ)

– Selectivity/specificity and system suitability

– Method linearity and range

– Method ruggedness and robustness

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

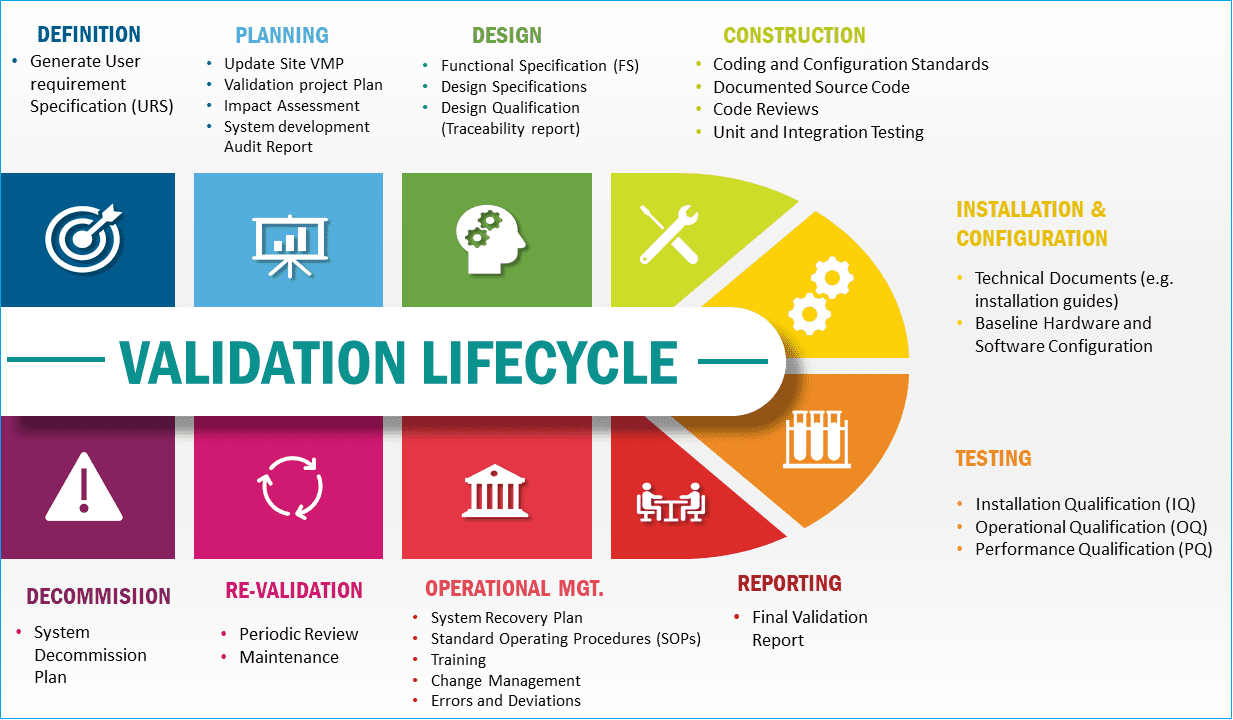

4. Process validation Vs. Computer systems validation?

Computer system validation (CSV) is related to process validation but is carried out using different strategies.

While process validation focuses on the consistency of manufacturing processes in producing quality products, the CSV focuses on supporting those manufacturing processes.

CSV ensures the automated systems are appropriately designed, installed, and performed according to user requirement specifications.

Validation of computer systems provides documented evidence to assure that they will consistently function according to their pre-determined specifications and quality attributes throughout their lifecycle.

Important aspects of computer system validation are:

– The formal management of design (through a specification process).

– System quality (through systematic review and testing).

– Risk (through identification and assessment of novelty and critical functionality).

– Lifecycle (through sustained change control).

Where equipment is controlled by embedded computer systems, computer validation elements may be performed as part of the equipment installation qualification and operational qualification protocols.

Implementing computer and computerized system validation is a structured process that aligns with the Lifecycle model and the principles of process validation discussed in this article.

This alignment ensures a systematic and thorough validation process.

Qualification documentation, in the case of computerized systems, may cover both the controlled equipment and the controlling system, maintaining consistency and comprehensiveness.

The image below summarizes the validation lifecycle. However, not all phases of the lifecycle detailed below are applicable to all categories of computer systems.

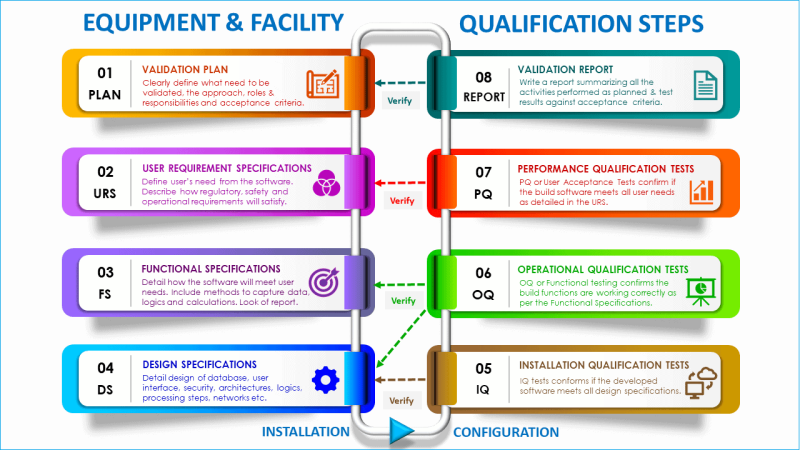

5. Process validation Vs. Equipment qualification?

Equipment and facility qualification, an integral component of process validation, is pivotal in ensuring the quality and safety of manufacturing processes.

It involves showing that the equipment and facilities you have used in the manufacturing facility are good for their intended use and meet the required quality standards.

The primary objective of equipment and facility validation is to guarantee that the equipment and facilities function optimally, thereby safeguarding the quality of our products.

The extent of equipment and facility validation should be based on risk assessment, and critical aspects and other system components or functions should be verified to be fit for the intended use.

The risk assessment should be based on the impact on product quality and patient safety.

Additional items for consideration include

– The level of standardization,

– Level of complexity,

– Configuration,

– Customisation,

– Intended use, and

– Vendor quality system assessment where applicable.

Equipment and facility validation plans should include periodic reviews of equipment validation status that come in contact with medicinal materials during the production process.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Main steps taken during equipment qualification?

During the equipment qualification process, you should establish and provide documentary evidence of the following steps:

Step 1: Design Qualification (DQ)

Design qualification intends to produce evidence that the equipment and the processes have been designed in accordance with the requirements of GMP, which include:

– Generation of user requirement specifications

– Verify that the design meets relevant user requirement specifications.

– Supplier assessment /audits

– Challenge of the design by GMP review audits

– Product quality impact assessment

– Specifying validation documentation requirements from equipment suppliers

– Agreement with suppliers on the performance objectives

– Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT) & commissioning procedures

– Defining construction and installation documentation to assist with Installation Qualification (IQ).

Step 2: Installation Qualification (IQ)

Installation qualification intends to produce evidence that the equipment has been built and installed in compliance with their design specifications.

Installation qualification will provide documented evidence that the equipment or system has been developed, supplied, and installed following design drawings, the supplier’s recommendations, and In-house requirements.

Furthermore, installation qualification ensures that a record of all the features of the installed equipment is available. There is also documentation to support satisfactory operation, maintenance, and change control.

Step 3. Operational Qualification (OQ)

Operational qualification intends to produce evidence that the equipment operates per the design specifications.

The operational qualification provides documented evidence that the equipment operates as intended within approved acceptance range of the equipment.

In cases where process steps are tested, a suitable placebo batch will be used to demonstrate equipment functionality.

All new equipment should be fully commissioned before commencing operational qualification to ensure that it is safe to operate.

All mechanical assembly and pre-qualification checks have been completed, the equipment is fully functional, and the documentation is complete.

Step 4. Performance Qualification (PQ)

Performance qualification provides documented evidence that the equipment can consistently operate within the performance specifications over a prolonged period and produce a product of pre-determined quality.

Performance qualification requires three product batches to meet all acceptance criteria for in-process and product testing.

Performance qualification requires the utility medium to meet all specifications over a prolonged sampling period for utility systems.

The performance qualification documentation should reference standard manufacturing procedures and batch records and describe the sampling and testing methodology to be used.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

What documentations are critical in process validation?

It’d be great if you could provide appropriate and complete documentation in your effort to process validation.

I’ve included a list of documents you should be able to maintain as supporting evidence of validation activities.

i. Standard operating procedures (SOPs) for equipment, processes, cleaning, and testing methods, which provide instructions for their use and maintenance.

ii. Master validation plan, which outlines the facility’s overall validation strategy and approach.

iii. Validation protocols and reports, validation activities, and results demonstrating that equipment and processes comply with regulatory requirements.

iv. Cleaning validation protocols and reports, which demonstrate that the cleaning procedures used in the facility effectively remove residues of previous products and prevent cross-contamination.

v. Risk management documentation outlines the facility’s risk assessment and risk mitigation strategy.

vi. Equipment and facility qualification protocols with results such as design qualification, installation qualification, operational qualification, and performance qualification.

vii. Manufacturing formulae

viii. Detailed batch documentation

ix. Change control systems

x. Investigational reporting systems

xi. Analytical documentation

xii. Development reports

xiii. validation deviation reports.

It is a regulatory requirement to maintain all validation documentation as evidence that your processes and facilities are operating as intended.

Validation records are used to determine if subsequent process development is necessary.

A revalidation program should be implemented based on a routine equipment revalidation schedule and site change management policy.

What does it take to be a validation engineer?

Certain qualifications are typically required to be a validation engineer in the pharmaceutical industry. These may include:

– A bachelor’s degree in a relevant field such as chemical engineering, pharmaceutical science, or biology.

– Superior knowledge of the regulations and guidelines set forth by regulatory agencies such as the FDA and EMA for the pharmaceutical industry.

– Experience working in a pharmaceutical manufacturing or development environment.

– Strong problem-solving and analytical skills.

– Strong communication skills, as the role often requires working with cross-functional teams.

– Knowledge of industry-specific software and technologies used for validation, such as computer systems validation (CSV) and laboratory instrument validation.

– Familiarity with Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP)

– Professional certifications such as Six Sigma, ASQ, ISPE, or GAMP can be beneficial.

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Conclusion

By now, you should realize that process validation is a critical aspect of pharmaceutical manufacturing.

Validation studies offer a remarkable level of assurance, ensuring that your manufactured products are safe, pure, effective, and of high quality for human use.

For robust validation practices, it’s imperative that pharmaceutical companies strictly follow the guidelines set by regulatory agencies like the FDA.

These guidelines encompass requirements for product design, development, testing, and documentation.

You should have a robust validation documentation system to claim your processes are validated and the systems that perform the actions within those processes are claimed to be qualified.

To ensure that validation is carried out effectively, you should develop a comprehensive master validation plan outlining the specific steps to different validation approaches.

This plan should include details on the specific tests that will be performed, the personnel responsible for carrying out the tests, and the timeline for completion.

With the overall knowledge of process validation in the pharmaceutical industry, you can establish a high degree of assurance that your manufacturing processes, activities, or systems will consistently and reliably produce a product that meets specifications and quality characteristics.

Quick takeaways

What is process validation?

Process validation is a series of activities undertaken to demonstrate that a manufacturing process can consistently produce a product that meets pre-determined specifications and quality attributes.

Why is process validation important in the pharmaceutical industry?

Process validation in the pharmaceutical industry is crucial to ensure product quality, compliance with FDA regulatory requirements, and the assurance that the process consistently produces safe and effective products.

What are the stages of process validation?

The 3 stages of process validation include the process design stage, process qualification stage, and process performance qualification to verify that the manufacturing process will consistently produce quality products under regular operating conditions.

How do you validate a manufacturing process?

To validate the process, you need to develop a validation master plan, identify critical process parameters, and conduct validation activities to collect evidence that the process consistently produces products with the desired quality attributes.

What is the importance of continued process verification?

Continued process verification is essential to ensure that a manufacturing process remains in a state of control by monitoring process data, implementing process controls, and making adjustments as needed to maintain quality and compliance.

What are the regulatory requirements for process validation?

Regulatory requirements for process validation involve documenting validation activities, conducting IQ and OQ of equipment, establishing process parameters and specifications, and demonstrating that a process meets quality and safety standards.

Who is involved in the validation team?

The validation team typically comprises professionals from various disciplines, such as manufacturing, quality assurance, engineering, and regulatory affairs, who work together to ensure the manufacturing process is validated according to industry standards.

What are the types of process validation?

The types of process validation include

– Prospective validation, where the process is validated before production.

– Concurrent validation is conducted during production, and

– Retrospective validation, where the process is validated using historical data and records.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.