Guidance Summary 091 - 100

Guidance 091 Summary - Microbiology Laboratory Management

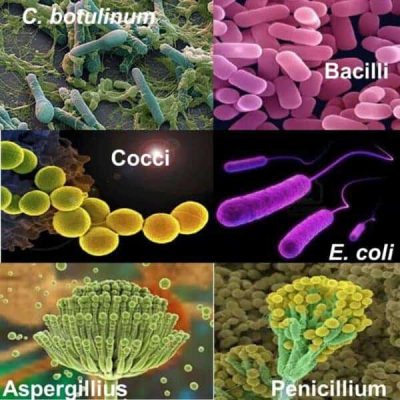

The management of microbiology laboratories includes Control and maintenance of reagents, reference standards, buffers, microbial cultures, and microbiological culture media; Monitoring and control of the microbiology laboratory environment; Calibration and maintenance of laboratory equipment and Documentation and control of microbiological test results.

Laboratory equipment requiring repair or calibration should be clearly marked and when beyond repair, the equipment should be removed from the laboratory.

An Equipment Cleaning and Maintenance Log should be maintained for each incubator and should include, at least, the following: Cleaning and/or disinfection of the incubator; Description of maintenance/calibration; Date activity performed; and Name/initials of person performing the activity.

Sterilized Equipment should be labeled with the cycle number and expiration date and stored in a manner that prevents contamination (e.g., in designated storage area). Wrapped, sterilized items should be inspected prior to use for dryness and to verify the integrity of the wrapping. Wet or torn, wrapped sterile items should not be used and should be removed from the work area.

Qualification of Personnel Performing Test Procedures should include demonstration of the ability to perform the test methods according to approved written procedures. Requalification in a test method should be required if the analyst has not performed the method during the past year or a significant change was made to the method since the analyst was last trained in the method.

Automated Microbial Identification Systems should be validated using a recognized reference source (e.g., ATCC, NCTC). For Microbial Identification Systems using cards or strips, the performance of each shipment of cards/strips should be evaluated using a set of known organisms. In systems requiring a complex sample preparation, a set of known standards should be included with each test performed to evaluate the system’s performance.

Guidance 092 Summary - Transfer of Analytical Methods

Responsibilities of the Transferring laboratory qualified personnel include: i). Identify the qualified personnel to lead, execute, and complete the transfer activities. If a facilitator or 3rd laboratory is used, then their responsibilities should also be identified; ii). Provide method specific information to the Receiving Laboratory qualified personnel; iii). Provide method specific training and support to Receiving Laboratory qualified personnel, as applicable; iv). Generate, review, and approve transfer documents; etc.

The Transfer Plan Document(s) should detail the following: i). The test(s) to be transferred, ii). The modes of transfer; iii). The justification for the modes of transfer selected; and iv). Pre-determined acceptance criteria.

If Acceptance Criteria are Not Met, qualified personnel at the participating laboratories should conduct an investigation to identify the potential cause(s) of the failure.

If the root cause for the failure is attributed to the testing laboratories or the transfer strategy, additional testing may be necessary and documented in a contingency testing plan.

If the qualified personnel at the participating laboratories determine that the transfer effort is to be discontinued, the reason for this determination should be documented and approved by the qualified personnel at the Transferring and Receiving Laboratories.

Guidance 093 Summary - Quality Agreements

Supplier can be defined as a firm that manufactures materials for the buyer site. These materials may be excipients, packaging components, RSMs, APIs and operations.

All materials comprising a finished drug product should have a Quality Agreement in place with the supplier, including suppliers of primary (direct product contact) packaging components.

Material list where suitable a table format including materials supplied and services performed may be helpful. If included specify that the supplier is responsible for all management and oversight activities, qualification, quality agreement, test or material results, etc. provided by sub-contractor. regulations, law, directives, guidances, compendia, etc.

Quality responsibilities should include 1. Conformance to agreed upon standards (such as national/local rules & regulations, law, directives, guidances, compendia, etc. 2. Inclusion of a specification describing the material (acceptance criteria, tests, methods, etc.)

Supplier should have in place a quality system that encompasses quality oversight of its’ suppliers that encompasses qualification, approval, management, oversight, audit, surveillance testing, etc.

Supplier should be knowledgeable regarding the manufacturing source and the individual supply chain organizations (re-packagers, broker’s, warehouses, etc.) that handle the product.

Quality agreements also requires supplier communication regarding Regulatory Agency activity (inspections, notifications, enforcement activities) impacting the supplied material (including the systems used to manage the material production, testing, handling and storage).

Guidance 094 Summary - Systems Validation

This document provides guidance in the validation of systems (facilities, utilities, and equipment, including process control systems, and information systems), that support regulatory compliance – practices, validated processes and/or systems used in the production or storage and distribution of Active Pharmaceutical Ingredients (API),

For direct impact systems, user requirements specifications (URS) should document what the system must do to meet internal specification, product and regulatory requirements.

For new direct impact systems, specifications should document the critical aspects of the system design, system functionality, hardware and software components and system configuration.

Specifications for custom systems or configurable systems should be approved by a Subject Matter Expert (SME).

For Legacy Systems that require validation, any documentation that describes the system on a functional and design level (e.g., vendor manuals, drawings, configuration documents) can serve as specifications for critical components and functions.

Component level impact assessments, when performed, should be documented and approved by the responsible validation committee.

The assessment results and corresponding action plan should be documented. The action plan should identify activities required to minimize the impact of any missing or poorly documented validation deliverables required for legacy systems. The validation committee should approve the assessment results and action plan.

For new direct impact systems, a design review should be conducted, to ensure the system meets regulatory requirements and is suitable for its intended purpose. The review should be documented (e.g., DQ or Design Review, validation report) and should be approved by the responsible validation committee.

Installation Qualification (IQ) should verify and provide documented evidence that any required commissioning activities are complete and those critical components have been installed and configured according to specifications.

Operational Qualification (OQ) should verify and provide documented evidence that critical components perform according to specifications, throughout defined operating ranges and meet predetermined acceptance criteria.

Performance Qualification (PQ) should verify and provide documented evidence that the system performs according to requirements, while integrated with associated systems, operates in the final production and/or validation test environment according to SOPs, and meets predetermined acceptance criteria.

Guidance 095 Summary - Metal Detection

The decision on whether routine metal detection operations are required for products at their Site should be based on, and not limited to, the following factors:

- Product history of metal contamination incidents (e.g., equipment failures, equipment metal-to-metal contact causing contamination, raw materials with metal contaminants);

- Assessment of manufacturing and/or packaging and labelling processes involved in terms of possible metal contamination.

- Effectiveness of the metal prevention systems and processes used at the site; and

- Commitments to Regulatory Authorities.

Action Levels for the total number of units (e.g., tablets, capsules, bottles) isolated by the metal detector should be developed by the quality based on the historical data on the number of units contaminated with metal according to product and/or manufacturing or packaging process step.

The Metal Detector should be positioned such that the detector does not interfere with the process and the detector is not in contact with adjacent manufacturing or packaging equipment. Any chutes or conveyors passing through detectors should be aligned to not interfere with reject gate operation.

All Metal Detectors used in Packaging Operations should be qualified and subsequently set-up and operated such that the detectors will, 100 percent of the time, detect and isolate spherical 1.0mm ferrous, spherical 1.0mm non-ferrous, and spherical 1.5mm stainless steel metal embedded in discs or cylinder carriers that are used to challenge the system.

Product Units (e.g., Tablets, Capsules, Packaged Units) that are isolated by the metal detector reject mechanism should not be returned to the acceptable units of the lot unless an investigation reveals an assignable cause associated with the metal detector. Product units that are isolated by the metal detector during re-inspection should be rejected and not returned to the acceptable units.

Guidance 096 Summary - Hose Management

GMP sites should have procedures defining the use, specification, storage, handling, cleaning and maintenance of hoses used in cleaning and production of intermediates and APIs in accordance with cGMP guidelines. Flexible hoses should be adequately identified, maintained and cleaned.

When developing site hose specifications, considerations should be given to dedicated hose vs. multi-purpose hose. If conditions allow, the preference should be for dedicating hoses to a specific use to prevent risk of cross-contamination. Dedicated or not, hoses should be tracked with unique identification and cleaned appropriately. Cleaning should always be made a requirement even if hoses are dedicated.

The hose length is typically restricted by the storage and handling procedure. It should be small enough for use but not so short to prevent excessive hose bends/kinks that can lead to premature mechanical fatigue/failure. It should be long enough for use but not so long to avoid impact on the effectiveness of cleaning. Avoid using multiple hoses, which are connected in series in order to extend hose lengths.

Only gaskets that meet or exceed the requirements of the chemical process and hose assembly specifications should be used for chemical transfer hoses.

A good hose preventive maintenance program should include the following:

- An SOP that sets processing requirements to ensure hose integrity;

- A program that provides documented tracking of the age and conditions throughout the life cycle of the hose;

Hydrostatic test – performing this test will help remove leaking hose assemblies from service.

A reliable hose preventive maintenance program will promote a longer hose life cycle and establish hose replacement frequency in the most economical way.

A written procedure for tracking hose maintenance including the use of tracking software, logbook or alternatives is recommended. This will assure monitoring on the proper maintenance, inspection, and testing throughout the service life of a hose.

Use and status of cleaning of hoses need to be traceable. Essential hose label information could be a combination of the following: serial/tag number, vendor name, manufactured date, hose materials, key hose design specs, unit/location assignment, last inspection/test dates, and first use date, etc.

Guidance 097 Summary - Use of Process Analytical Technology in Process Validation

PAT systems can be used to Collect data in parallel with the collection of traditional process validation data, Reduce the traditional validation testing or Replace a traditional test (regulatory or an in-process release test) during process validation.

Parallel PAT activity – traditional validation occurs without change while PAT activity is added and performed concurrently to traditional validation. The PAT provides additional information about the process, quality attributes and/or parameters. If the traditional process validation criteria are met but the PAT data suggest that the process might need further evaluation, an investigation should be initiated. If the PAT results are related to product quality, lot release should be held until the PAT investigation is completed.

If the data obtained from the PAT system will be used for parallel information to the validation tests only, the PAT application maybe considered an indirect or no impact system. Complementary validation data with the intent of reduced testing would be a direct-impact system. If the PAT data will replace a regulatory or an in-process release test that is not verified by another established quality test then the PAT application will be considered a direct impact system. Generally, if quality decisions are to be made based on the output of the PAT application, even if implemented with the parallel approach, the PAT application would be considered direct impact depending on the controls in place.

Guidance 098 Summary - Implementation of Process Analytical Technology

Implementation of PAT involves analytical measurement systems with associated methods that are integrated into a manufacturing process. Implementation of PAT applications should conform to current Good Manufacturing Practices (cGMPs).

Classification should be based on the intended use of the application, including the use of data generated. Subsequent impact to product quality and regulatory compliance should be incorporated into the classification assessment.

A PAT system or application whose operation, data, control, alarm or failure is expected to have an effect on product quality or regulatory compliance.

A PAT application that will produce, monitor, evaluate, store or report data used to accept or reject product or material, or data used to support regulatory compliance.

Each Site PAT application should be approved for use at the site by the Site Quality Team, including a review of its potential impact upon the quality systems at the site.

For PAT applications whose category of use is defined as Monitoring and Control, associated manufacturing and quality documentation should be revised in accordance with local change control policies in order to implement the PAT application at the site.

For critical (direct impact) and key (indirect) PAT methods, whose use is defined as Monitoring and Control, reliability of PAT applications should be periodically verified (based on risk) with a scientific and statistically-justified approach.

Guidance 099 Summary - Validation of Process Analytical Technology System

It is recommended that an impact assessment of each PAT system be performed. Those systems that are determined by the impact assessment to have a potential impact on product quality are considered direct impact systems and shall be qualified. Others which are determined to be indirect or no impact are Commissioned.

An impact assessment shall provide a risk-based approach to assess if a PAT system is direct, indirect or no impact, along with the extent of validation required for direct impact systems. Impact Assessments should be performed for all PAT systems. The System Level Impact Assessment (SLIA) shall determine if the system is considered to be Direct Impact, Indirect Impact, or No Impact with respect to its potential impact on product quality.

In the absence of a Component Level Impact Assessment, all components of a direct impact system require validation. Only critical components within a direct impact system require qualification. Non-critical components within a direct impact system are commissioned. For example, a PAT system could be defined as a system by itself. For PAT systems with fixed-installation probes, the most logical system boundary has the probe as part of the process equipment.

For systems that include laboratory instruments as part of the PAT system, the PAT system may first be categorized to determine if it has a direct, indirect or no impact on product quality.

The boundary for the PAT system has therefore been drawn to exclude the product contact components from the PAT system and include those components in the reactor system itself. This PAT system would require commissioning only. The system components in direct contact with product can be included within the scope of the PAT system and qualified as a component of the PAT system, or they can be included within the scope of the reactor system itself and qualified as part of the reactor system.

The boundary for the PAT system has therefore been drawn to exclude the product contact components from the PAT system, and include qualification of those components in the reactor system qualification. This PAT system would require commissioning only.

Quality risk-based, impact assessment of PAT systems and PAT applications is fundamental to establishing the validation strategy.

Guidance 100 Summary - Alternatives to Formaldehyde Fogging of Clean Rooms

What alternative methods exist to replace formaldehyde fogging of clean rooms?

Alternatives to formaldehyde fogging include the use of liquid sanitizers or fogging with an alternate chemical sterilant such as chlorine dioxide, vapor-phase hydrogen peroxide, or atomized peroxyacetic acid-hydrogen peroxide.

For biological facilities where viral contamination is a concern, it may be a regulatory expectation to decontaminate via fogging with some frequency. The switch from one disinfectant to another involves both laboratory and facility studies. The laboratory validation should include surveying the bioburden of the facility and determining the environmental isolate that is least susceptible to the agent.

The efficacy of the agent should then be tested against the least susceptible organism on representative surface materials found in the facility. Studies should then be conducted under actual conditions of use via surface monitoring of the facility both before and after application. Facilities are encouraged to actively pursue alternative sanitization methods. If the feasibility study indicates that formaldehyde use must continue, facilities should evaluate modification of the application process to minimize amounts of formaldehyde used, the airborne concentration of formaldehyde gas, and total exposure times.

A common use of formaldehyde at GMP facilities is to sanitize clean rooms following maintenance shutdowns.