Guidance Summary 011 - 020

Guidance 011 Summary - Rinsate and Swab Sample,Test Method Development and Validation

The guidance describes recommended approaches to develop and validate sampling and test methods for cleaning verification using rinse and swab samples.

Contents of Equipment Cleaning Analytical Method Validation Protocols should include

- Sampling Method

- Analytical Method

- Acceptance criteria including the Residue Acceptance Limit (RAL)

Method Validation

Method validation shall be performed in accordance with guidelines “Analytical methods for Equipment Cleaning”.

Method Specificity

The cleaning evaluation for a given product, intermediate or drug product excipient provides the basis for the rationale of which material(s) should be tested for during the analysis.

If a specific method is being validated for a cleaning agent, the only specificity experiment typically executed is specificity from swab extractables.

Range

The method is considered valid for any RAL within the validated recovery range. If the RAL falls outside the validated recovery range, the method should be revalidated with respect to

Linearity

The lower end of the linearity study shall take into consideration the correction factor for sampling recovery, if applicable (e.g. if the RALs have a range of 4-6 ug/cm2 and the recovery is 50 percent, the linearity study should include levels of 2-6 ug/cm2 ).

Recovery Studies

Analyte residue recovery shall be challenged as part of the analytical method validation. Recovery studies should include replicate or repeatability studies to confirm reproducibility of results. Site procedures may combine recovery from the surface and recovery from the swab in a single recovery study.

Site procedures should specify a minimum percentage recovery from the surface. For recoveries greater than 100%, no recovery values are to be used as correction factors.

Qualification and Training of Swabbing Personnel

If a special swab is required for a particular product it should be documented.

- Texwipe Alpha Swabs TX761

- Texwipe, Large Alpha Swab.

- Non Woven Swabs NT2300

Swab Pre-treatment

Area Swabbed

Choose solid, flat or semi-flat surfaces when selecting swab locations, if possible. Swab locations should be chosen based upon their difficulty to clean not the difficulty to swab sample.

A template of a non-porous material can be fabricated and used as a guide to ensure the individual performing the swab sample swabs the specified area.

Swab Standard Test Procedure Content

To facilitate the transfer of swab methods between sites and to achieve a greater uniformity of test methods at all gmp sites STPs or SOPs should include:

– Swab type

– Swab technique

– Swab area

– Surface types that the recovery is applicable to

– Extraction technique

- a) proving linearity of results from swabbing spiked coupons at a range of concentrations and compared to linearity of the test method, or

Equivalence of Methods Transferred Between Sites

If the validated range needs to be extended, then a separate swab linearity study should be performed by the receiving site over the required range.

Perform a recovery on 6 coupons using the receiving site’s procedure.

– Calculate the mean of the 6 recovery results. If the absolute % difference between the mean recovery and that stated in the originating site’s STP is not greater than 15%, then the recovery value stated in the STP will remain unchanged (e.g., if the STP states a recovery of 85%, then the receiving site

- Calculate the RSD of the 6 recovery results.

Guidance 012 Summary - Cleaning Validation – Visual Inspection and Quantitation

Visual inspection is the minimum requirement for all clean and test regimes required for Cleaning and Cleaning Validation. There are five aspects of visual inspection discussed in this procedure:

- Visual inspection following or during manual cleaning.

- Visual inspection of dedicated equipment

- Interval cleaning

- Campaign cleaning

- Routine Visual inspection of multi-purpose equipment

- Visual inspection during validation (e.g. most difficult to clean product approach)

- Visual Quantitation

- Laboratory Studies

- Difficult-to-clean inactive raw materials

If visual inspection is the only verification of a changeover cleaning process on minor equipment, the limit of detection using visual inspection techniques should be quantified in the laboratory or referenced from recognized literature.

Depending upon the desired outcome of the cleaning activity the visual inspection can take on different emphasis to achieve the desired goals. Visual inspection will be a part of all cleaning procedures developed, and as such, each site should define the significant operations, responsibilities and expected results within site SOPs or individual cleaning instructions.

- Visual Inspection following/during manual cleaning:

Manual intervention during the cleaning of major equipment is often required as part of a robust cleaning process.

The inspection should not substitute for the final visual inspection that would typically take place following analytical sampling. The final visual inspection determines the success or failure of the validation execution.

The purpose of inspection after manual cleaning is to measure the effectiveness of the manual methodology before resuming CIP cleaning. Rather, the inspection of these examples should follow the guidance of “final visual inspection” detailed below.

2 a. Visual Inspection of Dedicated Equipment – Interval Cleaning:

Product contact surfaces need not be free of visible residues if deemed appropriate by the cleaning evaluation activity.

The operations related to interval cleaning may be organized into their own cleaning instructions or it may be beneficial to incorporate interval cleaning activities into processing instructions (e.g., a post processing rinse).

2 b. Visual Inspection of Dedicated Equipment – Cleaning Between Campaigns:

Dedicated equipment campaign cleaning refers to the cleaning process performed between the end of one product campaign and the start of the next campaign of the same product. more emphasis during the cleaning process. The resource required to perform equipment disassembly on a routine basis, however, may justify the performance of a study to “validate” that the hard to clean areas are visibly clean for a number of consecutive cleanings as evidence that the visual inspection can be relaxed for subsequent cleaning.

- Routine Visual Inspection of Multi-Purpose Equipment.

For routine visual inspection of multi-purpose equipment, or those inspections that occur as the last visual check of a system prior to release back to production of the next product, consideration of the following is suggested as part of the development of a multi-purpose cleaning methodology:

- Visual Inspection during Validation.

During validation there may be reasons to perform more intensive equipment disassembly and visual inspection than during routine inspection. The routine cleaning procedure with any disassembly would be used in validation.

– Those areas identified as difficult to clean by the cleaning evaluation exercise should be visually inspected with disassembly as necessary.

- Visual Quantitation

If the only verification of cleaning changeover processes to be conducted on equipment is visual, then the visually detectable quantity must be known and documented.

Guidance 013 Summary - Cleaning Verification – Investigating Unknown Peaks in Chromatography

This procedure provides recommendations for conducting an investigation into unknown chromatographic peaks or spots/streaks observed during cleaning verification. Some unknown peaks may warrant further investigation when observed during verification testing for product and/or cleaning agent residues. A step-wise, methodical investigation should follow any decision to investigate the unknown peak.

Because unknown peaks observed in chromatograms for cleaning verification samples cannot be assumed to provide an equivalent response to a known standard, specific compound, Relative Response Factors (RRF) are typically not assigned to unknown peaks.

Single and Multiple Peaks:

Where more than one unknown peak appears in the chromatography, each peak should be evaluated individually (single peak evaluation).

Comparison of an unknown peak to the RAL determines if an investigation is initiated. The investigation of the sum of unknown peaks is technically challenging and

Limits

Response Factor

If an unknown peak is subsequently identified and a corresponding RRF established, the requirements of the investigation and the cleaning limit for that peak may be impacted.

Solvent/Cleaning Agents

Compare the peak to the solvents and/or cleaning agents from the manufacturing process and/or cleaning process to determine if the unknown peak is a result of solvent or cleaning agent interference. If an investigation into an unknown peak determines that it is due to an interfering solvent, then future observations of this peak would not require repeated identification of that peak.

The peak may also be the result of product degradation or reaction with the cleaning agent. If an investigation into an unknown peak determines that it is due to product degradation, then future observations of this peak would not require repeated identification of that peak. .

Sampling

Determine if the unknown peak is due to sample preparation, such as residues from lab gloves, sample containers or caps.

Guidance 014 Summary - Cleaning Evaluation Documentation and Records for Cleaning Activities

All cleaning practices requiring validation should first be evaluated and the results of the evaluation documented and approved. Every aspect of the cleaning practice should be reviewed including all materials and methods involved.

The cleaning program requires that cleaning is conducted and the cleaning activities documented following written instruction-records, or SOPs with attached checklists.

Cleaning instruction-records or SOPs with attached checklists, should include all relevant cleaning parameters and confirmation that significant steps have been completed.

Cleaning Evaluation Documentation

In order to appropriately document the development of the cleaning requirements for a material and/or equipment train, it is recommended that a cleaning evaluation report be prepared. Risk assessment tools may be useful in documenting the rationale supporting the cleaning.

Cleaning Instruction-Records

Equipment Cleaning Instruction-Records should be written in a detailed stepwise format for manual cleaning methods and in a defined sequential operation for automated cleaning contact time;

- Start and end times of each critical cleaning cycle or step;

- Method for indicating equipment cleaning status;

- Method for protecting clean equipment from contamination;

- Maximum time intervals for between use and cleaning;

Guidance 015 Summary - Critical Process Parameters for Drug Product

Guidance for evaluating a process to identify and define the critical process parameters.

A methodical approach should be taken to determining and defining critical process parameters.

A flowchart of the process and a list of the critical quality attributes (CQA) are useful tools for identifying and assessing the parameters of the process. An understanding of the concept and relationship between normal operating range (NOR) and proven acceptable range (PAR) is necessary in establishing the range for a critical process parameter.

Critical Quality Attributes and Critical Process Parameters

The critical quality attributes must be defined prior to assessing the manufacturing process for critical parameters.

Method of Defining Critical Process Parameters

Certain steps of the manufacturing process will affect the CQAs. A critical step may have one or more critical process parameters (CPP).

Alternatively, a critical step may not have any critical process parameters if it can be established that the parameter(s) in question has a NOR that is strictly controlled well-within the PAR.

One way of determining what is a critical process parameter is to begin with the CQAs.

The degree of control over the parameter will determine if it is critical. It is possible to have a critical step that does not contain any critical parameters if control of process parameters is tight. The step is critical but complete control over the parameters leads to defined noncritical process parameters. Critical parameters identified during the research and development phase are not necessarily reflective of production scale equipment.

Defining Ranges for Critical Process Parameters

An understanding of each parameter is necessary before defining a parameter as critical.

Parameters may be defined as critical depending on their effect on critical quality attributes, ability to be controlled, and the process design and capability. While knowledge of PAR values for a given parameter is important information for determining critical process parameters, it is the NOR that is used during process validation. Process validation requires equipment qualification and process data that supports the ability to control the process within the NOR, at a minimum.

Evaluate every possible combination of manufacturing process parameters. Instead, it is of the most benefit to document a thorough understanding of the process and the process parameters.

Guidance 017 Summary - Process Validation for Drug Products and Medical Devices

This GMP guideline provides guidance in the validation of manufacturing process for drug products and medical devices.

Critical Process Parameters -rationale for defining the critical parameters of a process should be documented, including Probable Adverse Consequences to be expected when critical process parameter ranges are not met.

Brief description of product, including product name, dosage form, and strength where applicable; critical processing steps to be evaluated and critical parameters to be monitored; specifications);

– The number of consecutive successful validation batches/lots needed to show consistent control of the process.

– Equivalency to existing drug products (where applicable) by comparison to previously produced batches/lots (commercial, development, or biobatches).

– Requirements to conduct homogeneity and hold time studies, if applicable; Critical process parameters and operating ranges, including justification for these (e.g., one-time studies on validation batches/lots using portable equipment, measuring equipment).

Representative samples should be drawn after critical process steps (e.g., freeze

- Number of specific drug product strengths;

- Number of drug product batch/lot sizes involved;

- Critical quality attributes;

- Critical process parameters; and

- Batch/lot size effects on equipment or processing capability.

Consistency should be demonstrated among the results of validation batches/lots. Development or carried out in conjunction with process validation batches/lots and documentation describing changes to the protocol;

- Test results;

- Review of critical process parameters from batch/lot production records; development, or biobatches), where applicable;

- Batch/lot processing and packaging records;

- Process control charts;

- Change control records (e.g., process equipment, facilities, and utilities);

- Process performance (e.g., capability studies); and

Major Changes – examples of major changes to an established process that require

- Changes in the acceptable range of a critical process parameter or a planned shift impact product quality;

- Fundamental change to manufacturing process or technology

Guidance 018 Summary - Equipment Cleaning Validation For Active Pharmaceutical Ingredients

A Cleaning Evaluation should be conducted, documented, and approved by the Site

Quality Team & Production Team. This evaluation may be a single report or several reports and may be equipment centric or process centric and document or reference the required information. The purpose of this documentation is to justify the decisions made in developing the cleaning validation protocols. This evaluation should determine or consider for each equipment unit:

- Solubility of residues in cleaning agents (including cleaning and rinse solvents);

- Cleaning parameters and applicable ranges (e.g., concentrations, temperatures, times);

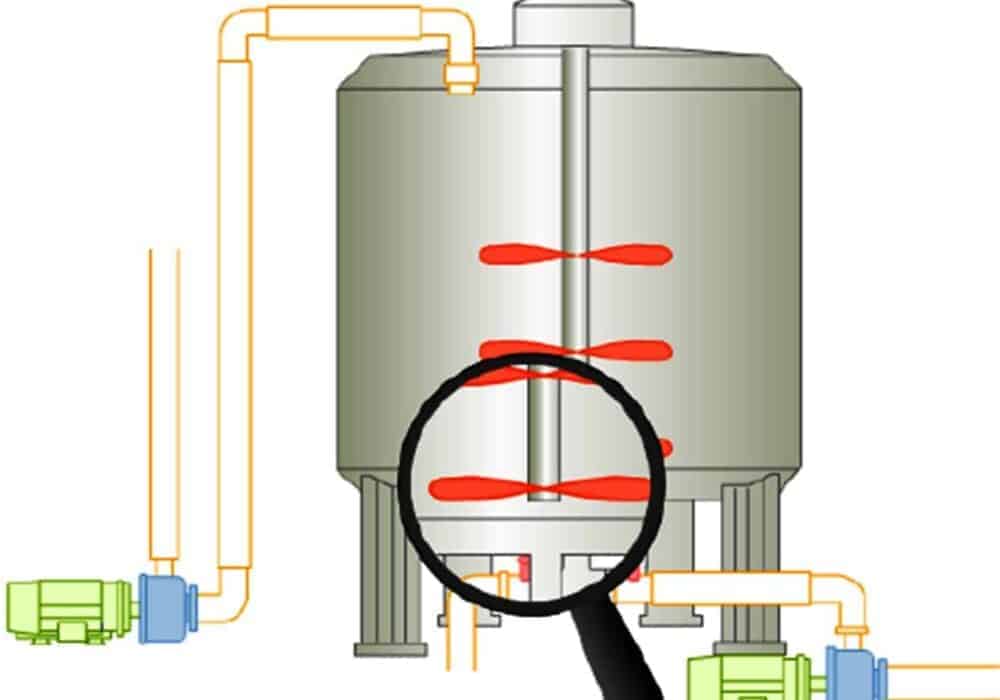

- Cleaning method (e.g., sprayball, flooding, power hosing);

- Extent of equipment disassembly;

- Potential for degradation by-products or conversion products;

- Stability of material(s) being cleaned under the proposed cleaning conditions; equipment;

- If equipment grouping is used, cleaning validation should be performed equipment within a group.

Selection of The Most Difficult To Clean Product or Process requires consideration

- Solubility of residues in cleaning agents (including cleaning and rinse solvents); cleaning operations;

- The Residue Acceptability Limit (RAL) required for cleaning;

- Cleaning history.

Rinsate Method – if a rinsate method is used as the sampling method, a measured calculated for each therapeutic product including clinical products (where dose).

If a worst case limit is used for equipment producing multiple compound types.

Guidance 019 Summary - Equivalence Criteria of Impurities for API Process Validation

This guidance provides recommendations for demonstrating equivalence of impurities to historic batches during validation of API processes for small molecules.

Existing impurities meet registered specifications when:

– There are fewer than ten historical reference batches, or;

– Reference data may not be representative of current process capability, or;

– The quantitative reference data do not exhibit a symmetrical distribution.

A more detailed discussion of these guidelines follows, along with recommendations to assist with statistical evaluations. batches and analytical tests for the equivalence comparison. For validation of a process to prepare a new API, the impurity profile should be comparable.

For some validations, insufficient reference batches are available for a meaningful comparison. For other validations, the availability of adequate reference batch data makes the use of statistical acceptance criteria more desirable because it enables comparison of the validation batches to established process capability data.

For validation of a process to prepare a new API, the impurity profile should be comparable to or better than the profile determined during process development, or for batches used for clinical or toxicological studies. For evaluation of a newly developed or modified process to prepare an API that is already commercially distributed, the comparison provides assurance that the process produces material that is equivalent to (or better than) acceptable material prepared in the past by an existing process, with respect to impurities.

Rejected, reprocessed, and reworked batches generally should be excluded from the historical set because they are generally not representative of the results expected from normal processing. Removing such batches for cause is permissible (thus breaking the consecutive nature of the batches), but batches should never be arbitrarily added to or excluded for the purpose of influencing the historical ranges of analytical results.

For residual solvents, a statistical acceptance criterion may not be appropriate in the validation of process changes that impact product drying. An acceptance criterion of “meets specifications” may be preferable in this situation. A process change that involves introduction of one or more new solvents to the process requires different considerations, and will usually require that registration specifications and/or ICH (Q3C) guidelines be met for the new residual solvent(s).

Guidance 020 Summary - Equivalency Comparison of DP Validation Batch Data to Reference Batches

This guidance addresses the equivalency comparison of manufacturing process data from drug product (DP) validation batches to previous batches (called “reference” batches), when applicable.

For new products, equivalency of validation data (e.g. finished product, critical in-process data, be considered for validation equivalency criteria.

Guidance is provided on

- A) Selection of reference batches for the comparison,

- B) Types of data that are compared for the most common dosage forms,

- C) General acceptance criteria, and

- D) Conclusion.

Typically, a larger number of reference batches are recommended for statistical purposes, if they are available. If available, data from at least 10 lots usually provide enough data to perform statistical analysis with a high degree of confidence. Potential reference batches may be excluded if deviations or failures are shown by root cause investigation to not be representative of normal processing. These exclusions should be explained with rationales that include why the batches are not representative of normal processing.

The historical reference batches should be predetermined and included or referenced in the validation protocol. Reference batches are usually the most recent (e.g. last 30 production batches). A link to original clinical batches is typically unnecessary if it is existing product that has already been validated. One does not need to repeat information in other documents such as regulatory submissions, Technology Transfer, Change Control or other Comparability or Equivalency studies. These studies can simply be referenced in the protocol.

Capsules-assay, impurities, dissolution, weight variation, content uniformity, moisture, microbial limits. Softgels may include leakage, appearance for precipitation/cloudiness.

Powder Blends-particle size distributions, density, API uniformity, moisture content, flowability.

Suspensions/solutions – assay, pH, viscosity, specific gravity, sedimentation volume / redispersibility / mean particle size, preservative content, microbial content.