Guidance Summary 051 - 060

Guidance 051 Summary - System Level Impact Assessment for Information Systems

This document explains how the Commissioning and Qualification System Level Impact Assessment template can be used for Information Systems.

It is recommended to base the system level impact assessment on the URS (User Requirement Specification) or other document(s) describing the system and system boundaries. An application profile (system description addressing the key functionality and how the functionality is used) may also be used to provide unambiguous information that is needed to answer the SLIA questions and to provide supporting rationale.

Different situations could arise when the system is used for restricting people access to manufacturing premises. Whether the system is direct impact and needs to be qualified depends entirely upon how the system is used. If it is the intention to act on the data that are generated and managed in the system and that action supports regulatory compliance-practices, then this system is a direct impact system and would require validation.

For information systems, the determination of system level impact will always depend on the type of data in the system and how the information is used, i.e. whether the data are acted upon and whether that action or decision is GMP-related; Additional questions to consider when performing the System Level Impact Assessment could be:

- What type of data is in the system?

- Do the data directly impact product quality or patient safety?

- Do the data directly impact the ability to recall?

- Are the data required by GxP regulation?

- How are the data (information) being used?

Guidance 052 Summary - Clean Pure Steam System Commissioning and Qualification - Sampling Plans

This document recommends sampling locations, frequencies, and testing activities associated with the commissioning and qualification of new installations or major revisions of Clean /Pure Steam Systems (e.g. the addition of new subloops or other system wide retrofitting).

Clean Steam is defined to be steam that does not contain any additives (e.g., boiler additives), 1 is used where the steam and/or condensate have direct contact with product, and the steam condensate meets USP/EPWFI requirements. In addition, clean steam that is used for sterilization applications of “porous loads” for international manufacturing also should meet the requirements of European Standard EN 285. The USP states that “Pure Steam [Clean] is prepared from suitably pre-treated source water analogously to either the pre-treatment used for Purified Water or Water for Injection”.

Qualification is an adjunct to commissioning and serves to provide documented evidence with oversight by Quality Assurance personnel that a clean steam system will consistently produce the appropriate quality of steam to end users in accordance with regulatory expectations.

A Clean Steam quality attribute may be defined as critical based upon the need to meet specific quality requirements where the quality is not enhanced further by additional downstream operating steps. For example, conductivity is a critical attribute that is measured at the outlet of a Clean Steam Generation System (e.g., condensate outlet of the clean steam generator) for verifying the results meet necessary steam quality requirements. Sampling the conductivity at this point would occur both during commissioning and qualification activities. For details regarding the design of a condensate collection apparatus for testing, refer to European Standard EN 285 – Sterilization-Steam Sterilizers – Large Sterilizers.

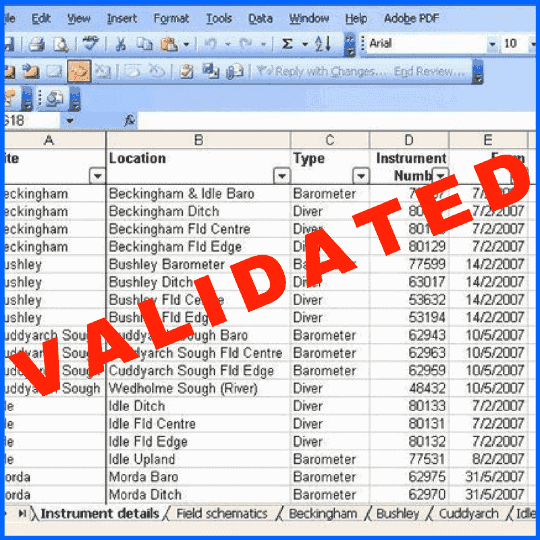

Guidance 053 Summary - Component Level Impact Assessment for Information System Application

In the absence of a component level impact assessment, all components of new direct impact systems must be considered as critical components and need to be qualified. However, if there is a documented rationale based on a Component Level Impact Assessment, components might be classified as non-critical based on their lack of potential to impact product quality or regulatory Compliance Practices.

A Critical Component can be defined as a physical element or function of a system where operations, contact, data, control, alarm or failure directly impacts product quality or regulatory compliance.

A non-critical component is defined as a physical element or function of a system where the operation, contact, data, control, alarm, or failure will have no impact on product quality or regulatory compliance practices.

However, not all functions that manage Critical Data are critical. The following three questions which supplement the above question may help in determining whether the function is critical. If one of the following questions is answered yes, the component is considered to be a critical component and must be qualified.

Examples:

- A function that generates data

- A function that stores data

- A function that processes data

- A function that manipulates data (calculations)

- A function that outputs data

Guidance 054 Summary - Cycle Validation for Freeze Drying

There are three elements to achieving successful validation of a freeze drying cycle:

- A well defined and understood formulation,

- A qualified freeze dryer and a freeze drying cycle that provides the link between a specific formulation and

- A specific freeze dryer.

The design of the formulation is based on the characteristics of the molecule to be freeze dried. Stabilizing agents are chosen and tested. The collapse temperature, or eutectic temperature, is identified and experiments are designed to determine a robust combination of the solution composition and the primary drying temperature. At this stage, the primary packaging (for example, vials, stoppers) are also defined.

A typical freeze drying process consists of the following stages:

– Filling

– Loading into freeze dryer chamber

– Freezing

– Secondary drying – at reduced pressure the shelves are heated to a specified temperature to remove bound water

A freeze dryer is mainly composed of two chambers, the chamber where the product is freeze-dried and the condenser that stores removed water.

- Shelf temperature monitoring and control

- Chamber pressure monitoring and control

The appearance of the freeze-dried cake or plug, is a key indicator of whether the freeze dry process has been successful.

It is recommended that each specific product and specific freeze dryer combination is considered separately.

- Equilibrium product temperature during primary drying

- Chamber dimensions, capacity

- Load configuration

Transferring a product to a new freeze dryer should include an evaluation of whether the existing cycle parameters are appropriate for the new combination. A science and risk-based approach may be taken to determine whether any trial batches are required or whether there is sufficient confidence in the applicability of the original cycle parameters that cycle validation may be initiated without trials. Cycle validation requirements for the transfer of an existing commercial cycle, including the number of runs needed, should be based on science and risk. Considerations should include the magnitude of the change, the process history, the robustness of the cycle and the complexity of the formula/container.

Batch sizes for freeze-dried products are generally defined by the capacity of the freeze-dryer. Cycle times are typically long and therefore the processing of partial loads is inefficient and unusual.

Guidance 055 Summary - Documenting IQ, OQ, PQ Protocol Test Results for Equipment, Facility and Computer

It is not good practice for the tester just to simply record a check mark (Pass/Fail), initials, or write “as expected” (or similar notation of acceptance) as the actual results without providing evidence of the result of the test step. Mark pass or fail especially when a reference or a numeric result should be recorded. Alternative documentation methods (e.g., the use of test keywords, codes, measured values or attachment references like screen prints, reports, etc.) may be utilized as long as the methodology is defined and provides unambiguous results.

Re-writing the entire text and measured values identified in acceptance criteria as the “actual results”. It is not good practice for the tester just to simply record a check mark (Pass/Fail), initials or write “as expected” (or similar notation of acceptance) as the actual results without providing evidence of the result of the test step. It is allowable to mark pass or fail as long as evidence is provided, especially when a reference or a numeric result should be recorded. Without an actual observed value or a screen shot, the assurance that the actual result was observed is limited. For critical steps, printed evidence should be included in the test results. For non-critical steps, it is not necessary to capture a screen if a test is incidental to proving a user requirement. However, where evidence cannot be produced during the execution of a critical function step, the test step result may be recorded in the Actual Results column.

It is good practice and required for a tester to sign/initial, date, and record the protocol number, test procedure number, step number on each page of a report or screen print. This is to help ensure that all pages remain traceable to tests. If the generation of a lengthy report is being tested, it is acceptable to only document the first page of the report.

Guidance 056 Summary - Material of Construction Documentation

This document provides guidance for allowing Vendor’s Material of Construction. Vendor-supplied documentation of material of construction is generally sufficient documented evidence for confirming that a specified material has been used in construction of the delivered system or component.

Materials of Construction for critical components (e.g., product contact) in both manufacturing and utility systems should be suitable for their intended use, in that they should:

- Be compatible with the product and any cleaning, passivating, sanitising / sterilizing agents.

- Be smooth and cleanable (where required).

- Be resistant to temperature extremes (if applicable).

- Not have Particle release (be low or non-fibre shedding).

- Not contribute foreign substances to the product.

- Be non-absorptive.

- Meet surface finish levels, where required and specified.

.Materials of Construction for critical components (e.g., product contact) in both manufacturing and utility systems should be suitable for their intended use, in that they should:

The manufacturer is allowed to transfer onto this inspection certificate relevant test results obtained by specific inspection, provided that the manufacturer operates traceability procedures and can provide the corresponding inspection documents required.

Risk of impact to product quality due to the MOC of the component (higher risk = greater documentation requirement) Agreement on the required level of documentation for the materials of construction (MOC) needed to be supplied by the manufacturer (or their intermediary), should be reached early in the Design/Procurement phase for systems and components being purchased and built into the purchase specifications.

It is important to note that while classification of a metal may be determined, it would not be expected that specific alloys within metal classes (e.g. 304, 316L Stainless Steel) could be identified using the described visual identification methods. It is recommended that if the metal class has been determined via visual inspection, that it be documented along with the justification for the material’s suitability for current use.

Guidance 057 Summary - Packaging Process Documentation Transfer for Drug Products

A Packaging technology transfer of an existing DP packaging presentation to a different site often involves a change in registration documentation for the product, to include the new location. Therefore, validation requirements for packaging and support systems at the receiving site should be considered at an early stage of the packaging technology transfer process. The Site Master Validation Plan should also be updated accordingly. Validation requirements for processes, cleaning, analytical methods, and systems (equipment, facilities, utilities etc) should be documented in Site Quality Standards.

When only the packaging process is transferred, the documentation from the sending site should be focused mostly on product quality documentation and product history. When the packaging equipment is also included as part of the transfer, the documentation to be transferred will include equipment documentation such as calibration, qualification, cleaning certificates, SOPs, maintenance logs, etc.

Evaluate if the qualification documentation provided by the sending site will meet site requirements. If not, the receiving site can develop a plan to address the missing information. If documentation is acceptable then evaluate if any additional testing is required from an operation range stand point. If an operational range needs to be extended then OQ testing will be required. If the product and process requirements are satisfied no additional OQ testing is required.

Guidance 058 Summary - Purified Water and Water for Injection System Commissioning and Qualification Sampling Plans

Sampling and monitoring of the Pre-treatment, Generation and Distribution Systems for PW and WFI Systems during commissioning are considered Good Engineering Practice. These activities help to define operational and maintenance practices and procedures that will be challenged later during qualification. The sampling and testing activities include chemical testing as appropriate for unit operation and microbial testing to identify the indigenous microbial bioburden of the system. Typically, the duration of commissioning activities may vary depending upon the complexity and size of the system. Once the entire system is operating, each unit of operation should be tested at least once during the commissioning phase.

A water quality attribute may be defined as critical based on the need to meet a specific compendia specification and is not further affected by additional downstream operating steps.For example, conductivity is a critical attribute that is measured at the outlet of a PW Generation System (e.g., outlet of the Continuous Electrodeionization (CEDI) or Reverse Osmosis (RO) for verifying the results satisfactorily meet compendia limits. Sampling the conductivity at this point would occur during commissioning and qualification activities.

Non-critical quality attributes (e.g., outlet of the media filters,) are tested only during commissioning. Thus they may become part of an on-going routine monitoring program subject to Good Engineering Practices (GEP) which may include routine monitoring tests to assure proper maintenance and operation of the System (e.g., regeneration of resin beds, sanitization of equipment, etc.). This on-going monitoring on non-critical attributes is not to be a part of the qualification studies.

Guidance 059 Summary - Quality Considerations for Direct Impact Compressed Air and Nitrogen Systems

It is desirable that the quality of the compressed air and nitrogen is assured through adequate design, appropriate controls (e.g. change control, procedures), and routine maintenance of the system. If these controls are in place, direct-impact compressed air and nitrogen systems typically do not require analytical testing to be conducted. Routine release testing (e.g. identification testing) of vendor supplied compressed air or nitrogen shipments may still be needed for release of these incoming raw materials. This release testing is outside the scope of this guidance. The development of specifications for compressed air and nitrogen systems is typically conducted during the engineering design phase of the system, with documented verification of the systems’ suitability for intended use conducted during commissioning and qualification.

During the design and construction phases consider other potential contaminants, such as cutting oils or cleaning agents used in system construction or subsequent maintenance activities. A risk-assessment can be conducted to assess the likelihood of other contaminants being present and to assist with the elimination of their sources, or development of a testing strategy if necessary.

If moisture content testing is determined to be necessary, limits for moisture may include applicable EP pharmacopoeia limits. 5 Moisture levels are typically controlled via adequate system design, operation and maintenance. They are typically monitored continuously using on-line instrumentation and associated alarms. For air and nitrogen systems where the level of moisture is considered critical, the instrumentation and alarms associated with the monitoring of moisture levels are commissioned and qualified.

Guidance 060 Summary - Product Quality Complaint Handling

This Complaint Handling guidance defines practices for establishing and maintaining a product quality complaint handling system, and for monitoring and reporting corrective actions based on the findings. The investigation of complaints related to product quality provides opportunities for improvement in customer satisfaction with products and services.

The complaint handling system should make provisions for analysis of trends and effectiveness of corrective actions.

Any possible failure of a drug product to meet any of its specifications. Quality complaints may be of a routine nature, or may be determined to be a potentially serious quality complaint allegation, and will be classified as an Expedited Complaint for the purpose of accelerating the complaint investigation and submission to the appropriate regulatory agencies and/or competent authorities, if necessary.

The sample should be properly identified with the complaint file number and stored in a designated secure area. If the samples are to be returned to the customer after evaluation, or if destructive testing is to be performed, consideration should be given to photographing the properly identified sample. Once the sample is evaluated it should be stored according to procedure.

A typical Investigation Report should include the following information, as appropriate:

- Documentation of the Batch Record review

- Review of analytical records as indicated for atypical data

- Results of examination or testing of retention samples, product from stock, and/or stability samples

- Any information provided by the complainant that could aid in the investigation

- Review of lots produced before or after the subject lot

- Examination or testing of the complaint sample

- Review of the complaint database for trends pertaining to similar events, similar products, and/or similar materials.

- Documentation of any medical, legal, expert, or literature review.

- Any planned or completed corrective actions.

- Any other supportive or pertinent follow-up information for the investigation.